Expertly Optimized Solutions

High Temperature Systems, Inc. has a long history of being a solution provider in the melt department by developing, manufacturing, and installation guidance for molten metal circulation and transfer pumps. In the past two years, we have made significant changes in our business that allow us to become a true Solution Partner by providing higher levels of customization, automation; as well as consumables and instrumentation.

Solution Partner

High Temperature Systems, Inc. partners with melt department managers, supervisors, and engineers to craft complete solutions and solve problems that are beyond the reach of industry off-the-shelf solutions. Drawing from our standard product lines and more than 50 years of experience, we can craft solutions unique to your applications and furnace implementations. These solutions encompass aluminum, zinc and lead operations from die casting to galvanizing.

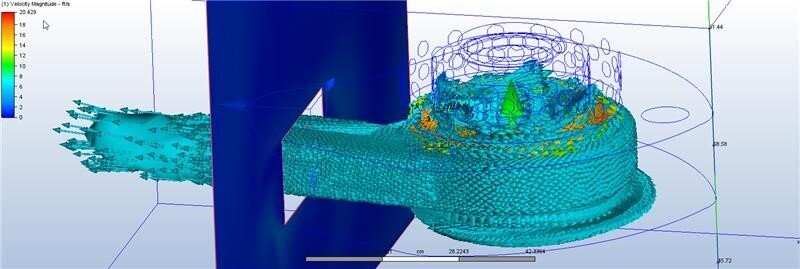

Driving Innovation to New Heights

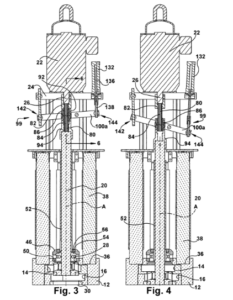

High Temperature Systems, Inc. continues to be the leading industry innovator in the field of molten metal circulation, transfer, chip melting, and rotary flux injection. Design innovations include revolutionary dross reduction circulation technology, dual-mode pumps that combine circulation and transfer (to reduce well space requirements) as well as high-performance rotary (or lance) flux injection systems. We continue to introduce new products and innovative features every year.

Deeper Integration and Automation

To ensure consistent results in the melt department, High Temperature Systems, Inc. has become experts in automating critical workflows such as rotary flux injection for aluminum purification. Optimal results require precise timing and metering that are beyond the role of most melt floor operators. Simple interfaces and one-button control ensure the best outcomes from every shift; while remote monitoring allows engineers and supervisors to stay in touch with operations.

Optimized Designs for Your Application

Our base pump designs, document control, and manufacturing process have been developed to streamline customization without expensive engineering efforts. Simple customizations, such as pump height, are typically provided without engineering expense. More complex customization may include a reasonable engineering fee.

Simplicity

In many cases, the optimal customization leads to simplified and streamlined solutions. The customization process begins with defining the abstract requirements independent of a specific pump design. This allows our experts to find the simplest, most economical, most robust solution. Once engineering has converged on a solution, various standard elements are brought together to complete the design. This design is then reviewed for sign-off by the customer.