Close Style Molten Metal Transfer Pump

Open Style Molten Metal Transfer Pump

Transfer Pumps

Molten metal transfer pumps are used for a range of applications including critical workflows like moving molten metal from melting furnaces to holding furnaces and transport ladles, but also for alloying and maintenance applications that require furnace pump-out.

Our pumps are proven to operate better than traditional tap-out configurations because they are designed to minimize oxidation and dross generation during the transfer and allow the option of remotely controlling the transfer start, stop, and rate. These capabilities allow operators to safely perform the transfer operation, while reducing labor and time required.

High Temperature Systems, Inc. has a three different transfer pump options:

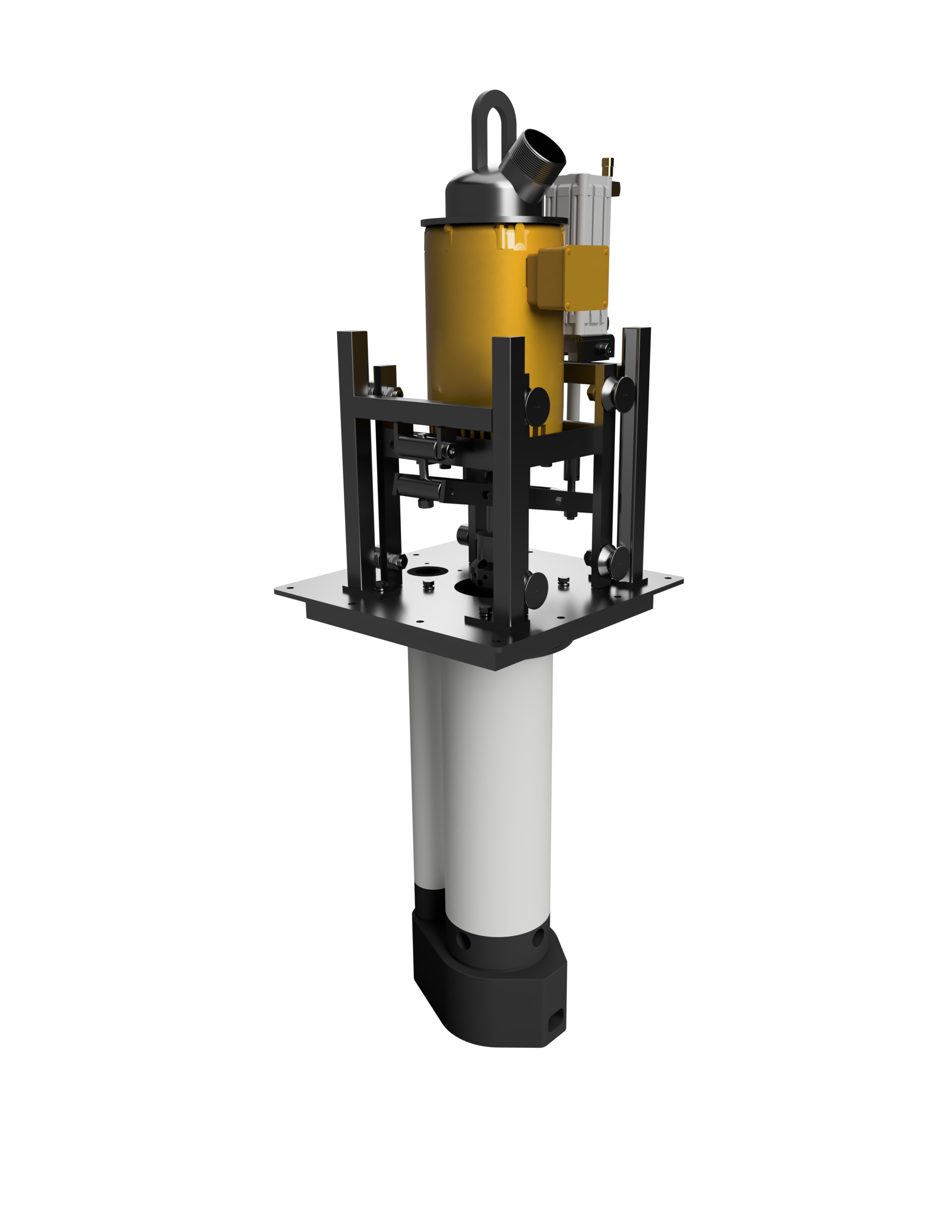

Open-Style Pump - Supported by Posts

The open-style pump has an open, easy to access shaft, making the shaft easily accessed for cleaning and inspection.

While the assembly remains in the melt, you can remove the shaft and impeller by lifting them up from the pump assembly, easing shaft and impeller maintenance.

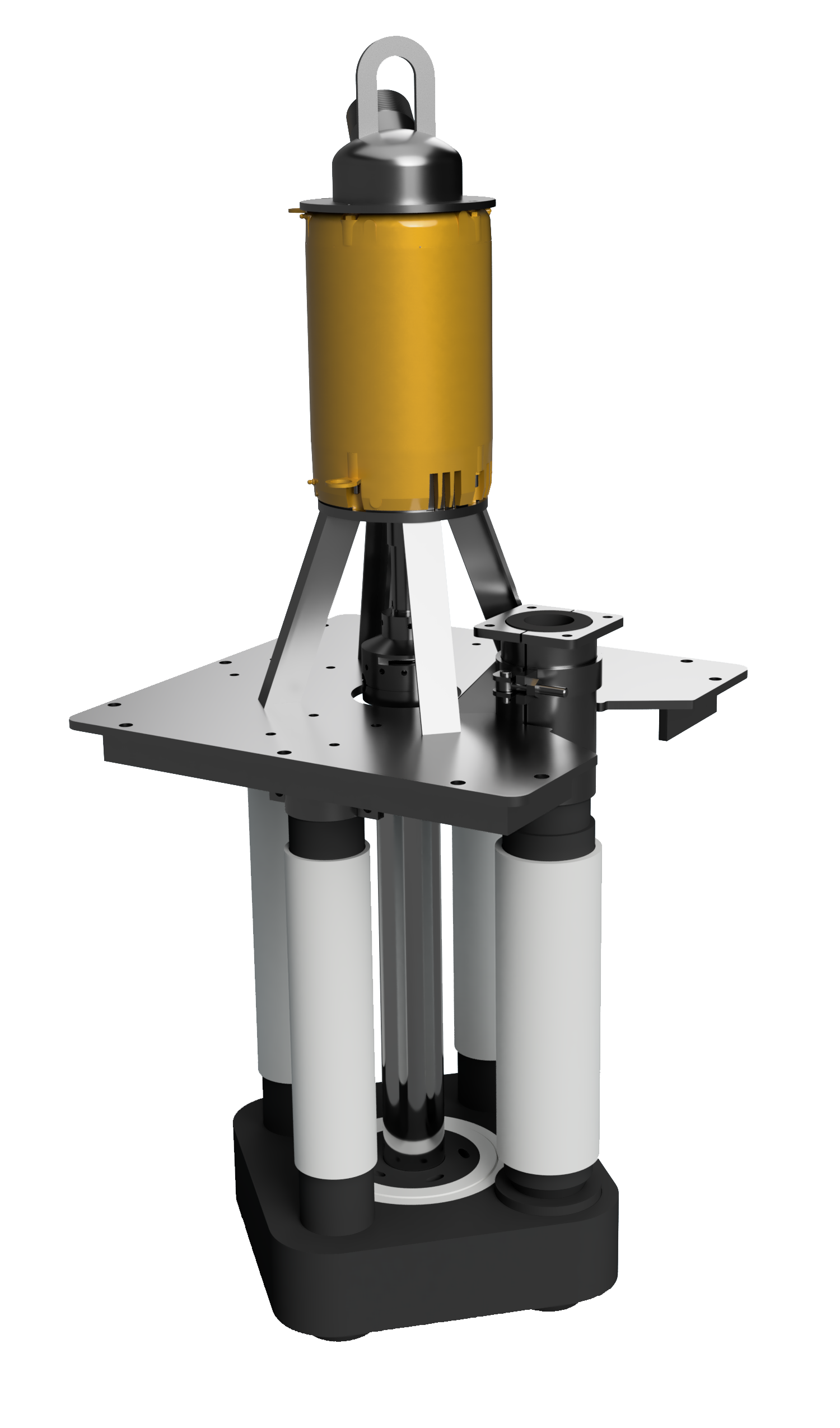

Closed-Style Pump - Enclosed Shaft Support

The close-style pump has an enclosed shaft that is housed in a protective refractory sleeve. While this prevents easy access for inspection and cleaning, the pump is optionally fitted with an inert gas feed that:

This pump can be fitted with an inert gas fitting to remove all oxygen present within the sleeve

Removing the oxygen eliminated oxide buildup at the metal level

Removing oxides will drastically improve lifetime of pump components

Cons: Requires a nitrogen/argon supply

Dual Position Pump - Enclose or Open Options

This pump would contain a transfer position as well as a circulation position

This would be useful for the alloying furnace to mix the aluminum into solution

We will have to discuss sizing and run some calculations to ensure that we can meet both circulation and transfer targets

Refractory Lined Pipe or Launder?

Refractory lined pipe provides a quality alternative to open launders. Unlike a launder system, the enclosed nature of the refractory lined pipe virtually eliminates atmospheric oxygen and surface turbulence, thus radically reducing dross generation. Learn more here.

Benefits

Start/Stop ability allows you to turn the pump off during transfer without seizing - allowing greater control and safety and reducing rebuild requirements.

Simple design reduces inventory parts requirements while reducing replacement time for a shaft/impeller combination to 5 minutes.

Safety Coupling and shear pin protect the shaft and impeller from premature failure reducing repair/replacement costs.

Proprietary oxidation resistant treatment of submerged components with 100% penetration greatly extends service life.

Maintenance Applications

Quick Pump

™

Maintenance applications include alloy changes, planned furnace maintenance as well as emergency situations. Alloy changes, while infrequent, often require substantial amounts of metal to be placed in sows for storage.

This process can be made much more efficient by using a transfer pump - such as our Quick Pump™ shown here - equipped with refractory lined pipe. This same configuration is also ideal for streamlining planned furnace maintenance or furnace shutdowns.