Articles

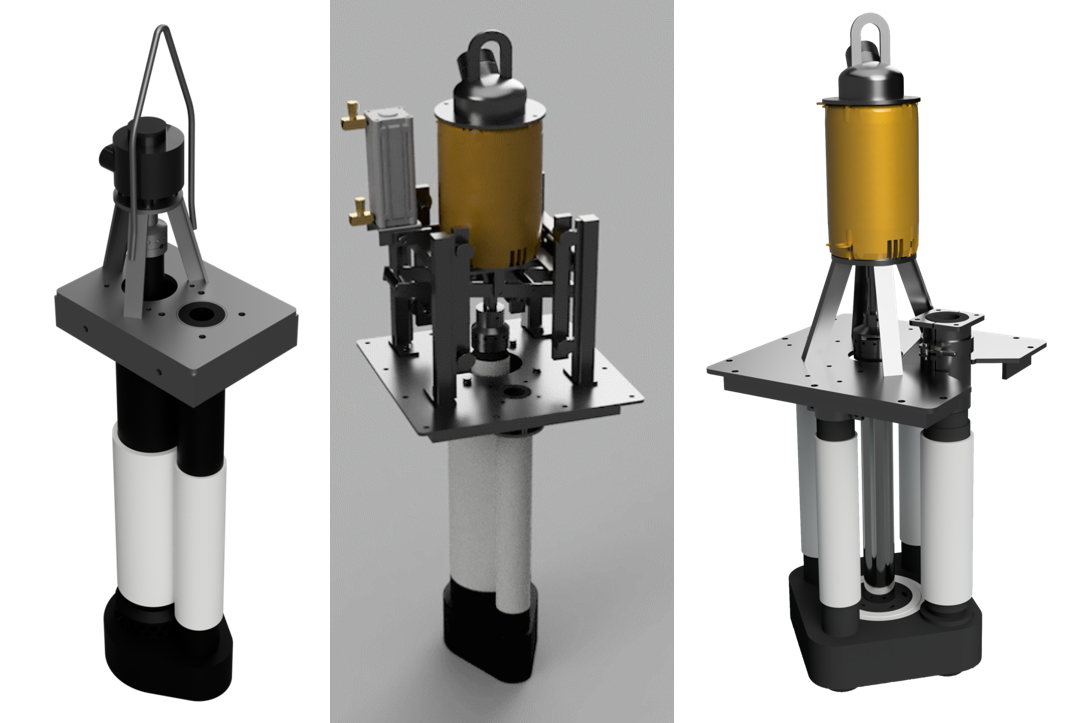

Transfer Pump Types

Closed, Dual Position, and Open Style transfer pumps are available in a range of sizes to accommodate any applications.

Intelligent Control for the Smart Foundry

Nearing the quarter of the 21st century, it seems technology is advancing faster and faster every year. Why shouldn’t your facility advance too? This post will provide some options for you to consider as you’re researching, designing, and improving your process.

Low Air Flow Freezes Pumps!

The primary reason for molten metal pump freezing is "slow starts." A slow-start is defined as slowly increasing the motor RPM. When a transfer pump is slow-started, the hot metal flows gradually into a cooler riser. As the metal temperature decreases, it solidifies or freezes inside the riser. This slow-start condition typically results in permanent damage and the need to rebuild the pump or at the very least replace the riser.

Graphite - Non-Wetting in Molten Zinc

Re-use of a Graphite Pump - Not a Warped Idea!

Unlike stainless steel pumps, graphite pumps can be quickly and easily reintroduced into the molten metal bath, and the pump will operate with the same efficiency as when removed from the melt. This capability is because graphite retains its structural and dimensional integrity while stainless steel becomes flexible and deforms at molten metal operating temperatures. Once removed from the metal bath, especially an aluminum bath, the stainless steel pump must be discarded due to excessive deformation. Molten metal pump base showing posts, shaft, shaft bearing, and base all made of graphite treated with a proprietary oxidation inhibitor process not available elsewhere.

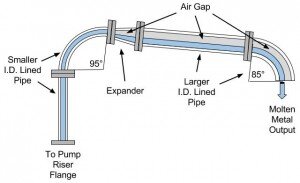

Like a Launder, Only Better!

A launder is used to transport molten metal. The basic construction of a launder is a steel trough lined with refractory material to insulate the molten metal from the steel. (Insulating both thermally and chemically.) The molten metal will lose heat as gravity draws it down the launder. If the heat is lost too quickly, the metal will freeze in the launder. There are a number of factors that influence the rate of heat loss including:

Pre-Storage Pump Inspection - Maintenance Pumps

Before putting a pump away for storage, it must be inspected. This article covers the step-by-step process to take before stowing a pump.

Preparing the Pump for Storage - Operational Assessment and Removal from Metal

About 10% of pumps are used exclusively for scheduled furnace maintenance. Between usages, these pumps need to be properly stored and maintained.

Rock Catcher Basics

Rock Catchers are used to keep large chunks of material from interfering with proper pump operation. Rocks, chunks, clumps, are all terms to describe material in the melt that is a bit too large to flow through the impeller’s orifices.