Circulation Pumps

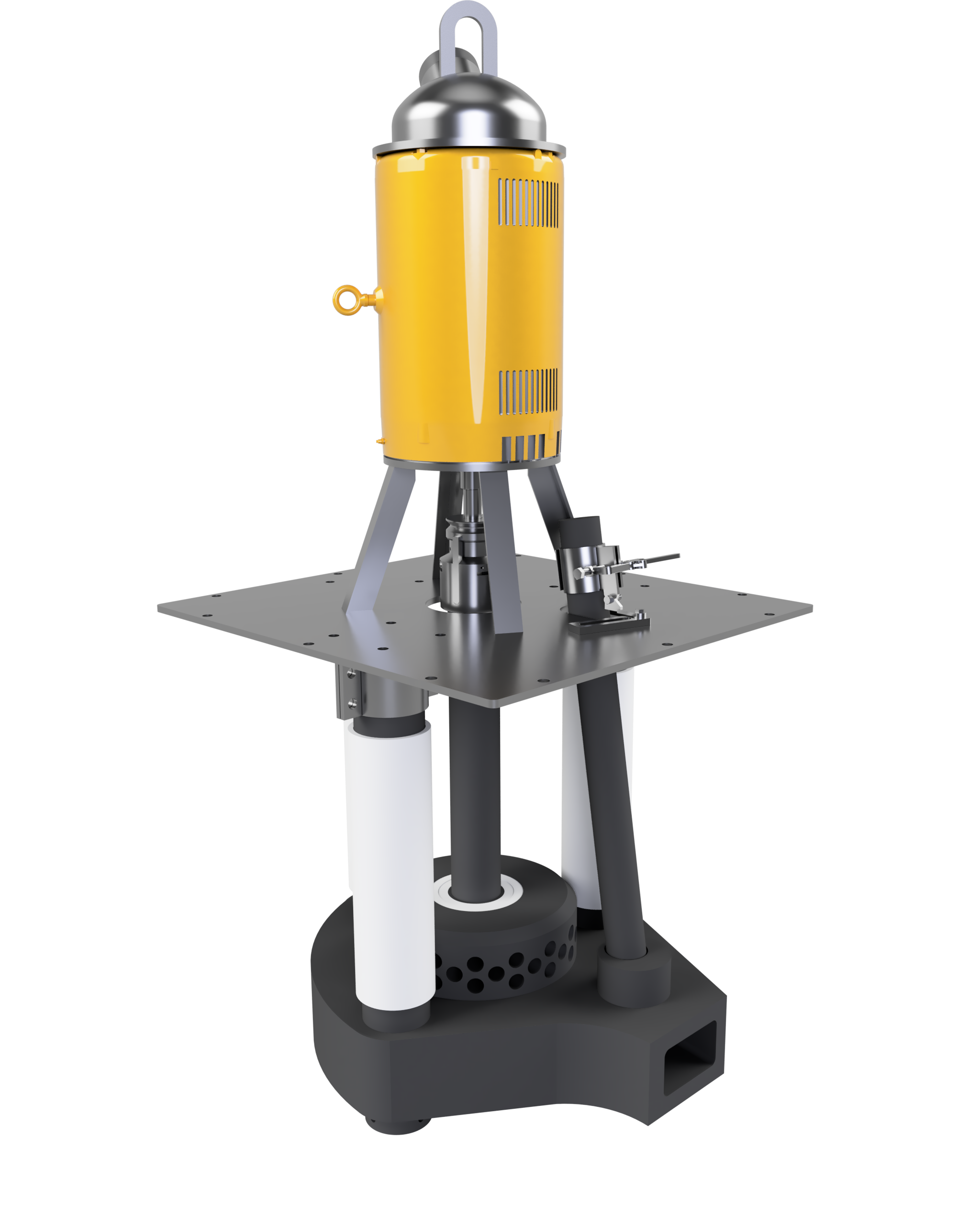

Standard Series Circulation Pump

Circulation is predominantly used for aluminum reverberatory melt furnaces to increase the overall operational efficiency of the furnace, reduce energy consumption, and boost metal quality

Circulating molten metal within a furnace has a range of benefits that include the following:

Improved Metal Quality – Circulation improves mixing and ensures homogeneity

Reduced Melt Loss – Circulation reduces oxidation by submersing the charge more quickly

Less Dross Production – By reducing peak heat by ensuring a uniform the melt temperature

Improved Furnace Refractory Life – By helping the flux to clean sidewalls and corners

Reduced Energy Costs – By reducing peak flue temperatures

Increased Production Throughput – Circulation reduces furnace cycle times

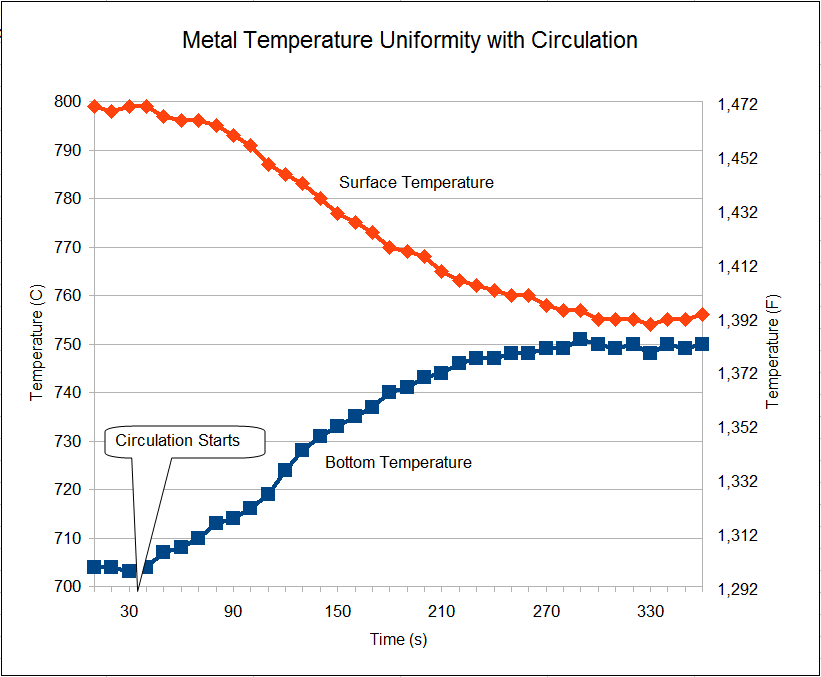

Melt Temperature Uniformity

To ensure a homogeneously alloyed metal bath, the entire aluminum bath must be held at a minimum temperature of about 700˚C. To achieve this temperature at the bottom of the bath (furthest from the heat source) without forced circulation, the top of the bath must be heated well over 700˚C.

This timeline shows the top and bottom bath temperatures both with and without forced circulation. At the far left, the chart shows typical bath temperatures for a modern reverb furnace without forced circulation in operation. Circulation is initiated at 30 seconds, and the bath temperature becomes nearly uniform within 300 seconds.

The most obvious benefit to forced circulation is energy savings. While energy costs fluctuate radically, energy savings is always a benefit to the melt department. With lower energy consumption, there is less stress placed on a range of furnace and facilities components. Most obvious is that flue temperatures can be lowered a few hundred degrees which reduces wear on the flue and scrubber components. Furthermore, the refractory liners will last longer at lower temperatures.

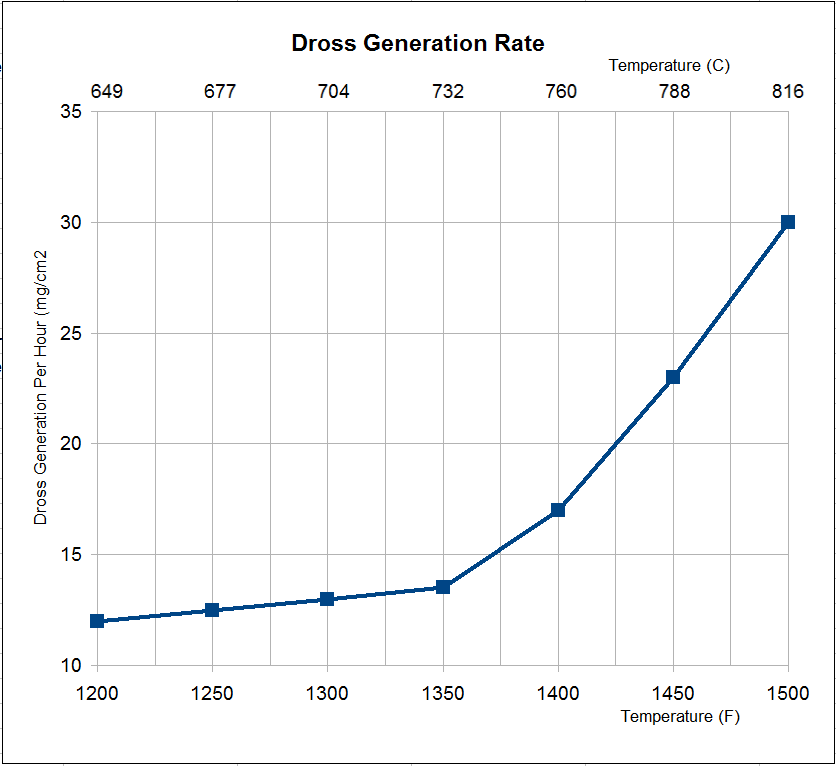

Reduce Dross Generation Rate

Dross generation is a function of temperature and availability of reactive chemical agents. The chart at the left shows the dross generation rate as a function of melt bath temperatures. There is an inflection point in the curve at about 730˚C above which the dross generation rate increases significantly. One way to reduce dross generation is to keep the melt temperatures as low as possible without impairing the overall operating efficiency of the furnace.

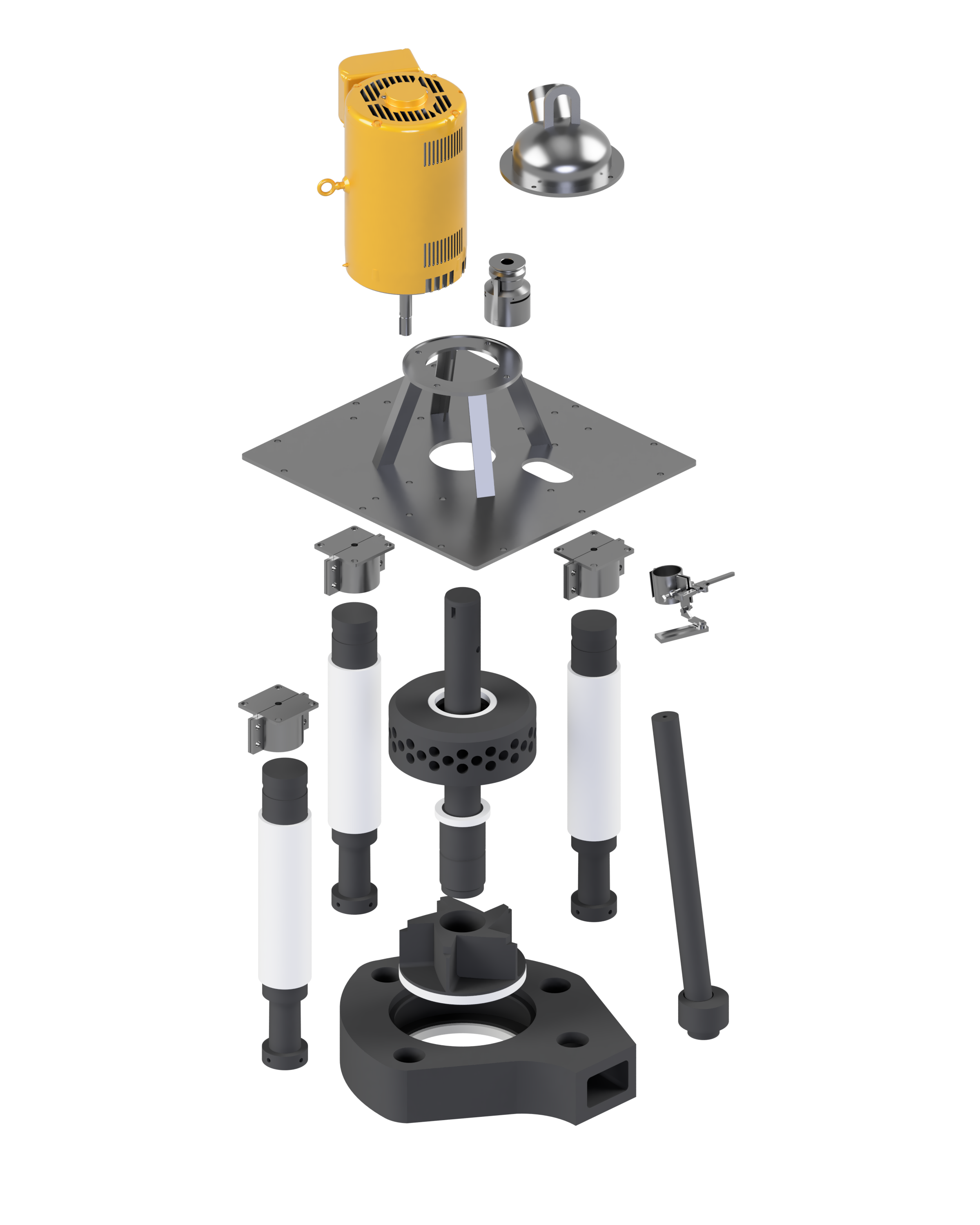

Circulation Pump Exploded View

Circulation pump options include:

Inline filtration

Single/Dual intake penteller impeller

Quick Disconnect shaft coupling

Cement-less design

Flux/Gas injection

Precise speed control via VFD