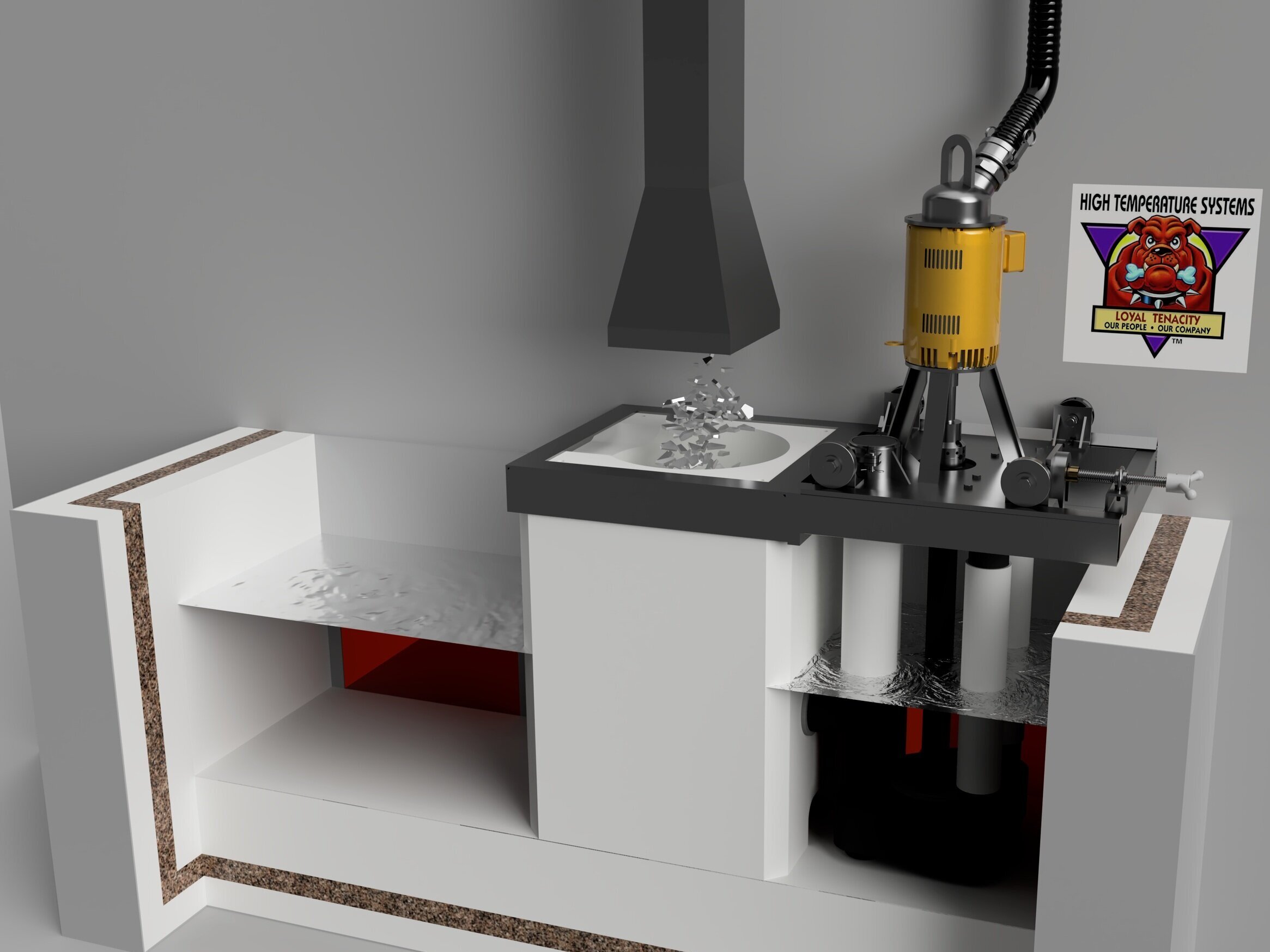

Recycling - Aluminum Chip Melting System

Coriolis® Chip Melting and Circulation System in an Aluminum Reverb Furnace

The Coriolis® Chip Melting System is a continuous scrap submergence system with the added benefit of forced circulation. The attached pump generates a strong vortex, coating and submerging aluminum chips in the metal bath, allowing for easily automated furnace filling.

Vortex Melting Features, Benefits, & Capabilities

Patented dual-volute design maximizes melt rate

Proper balance between melt and circulation flow

Standard and customized solution for every size of reverberatory furnace

Only available from High Temperature Systems

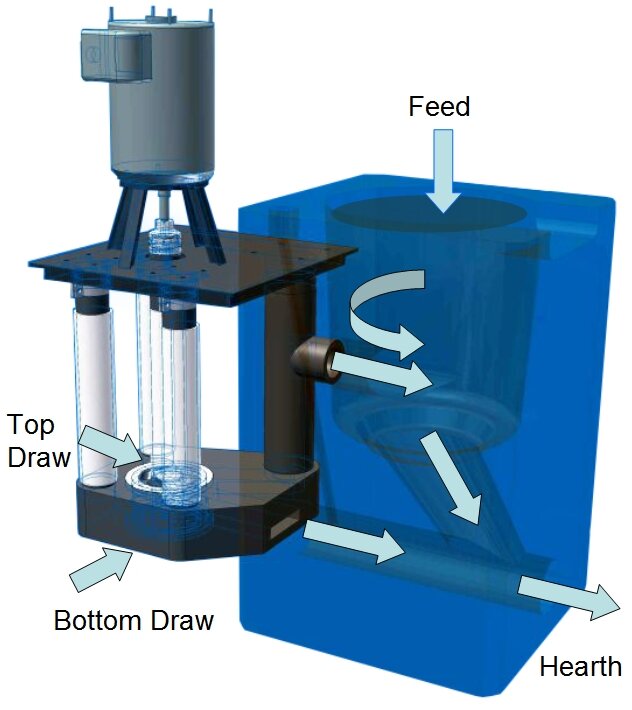

Dual Discharge Streams Drive Submergence Vortex and Circulation

The patented dual volute technology provides independent streams of molten aluminum for melting and circulation. As shown, the pump provides metal discharge from both the foot of the pump and the riser pipe. The diagram on the left shows the two streams of metal interacting simultaneously with the Coriolis® block. The upper stream from the riser drives the vortex mixer, while the flow from the lower outlet draws metal from the base of the vortex and provides a steady stream for furnace circulation.

Self-aligning Pump Mount Streamlines Pump Maintenance

Besides the dual-volute pump, there are several patents covering the melt system with respect to the vortex bowl design that enables balanced melting and circulation. The Coriolis® Chip Melting System also includes a self-aligning pump mount that ensures that the pump aligns with the ceramic vortex bowl after being serviced. The mount takes the guesswork out of routine maintenance and reduces downtime.