Molten Metal Pumps

Molten metal pumps or melt pumps are used for transporting liquid metal from an initial furnace or crucible to a desired final location or for forced circulation of furnaces - critical for optimizing furnace operation to reduce energy use, improve metal yield, improve temperature and chemical homogeneity, and maximize furnace throughput.

In the casthouse, pump systems can be used to transfer molten aluminum from the melting furnace to a transport ladle or directly to the casting cells, using refractory-lined piping to reduce oxidation and improve operations safety. HTS provides both standard and custom solutions for any application.

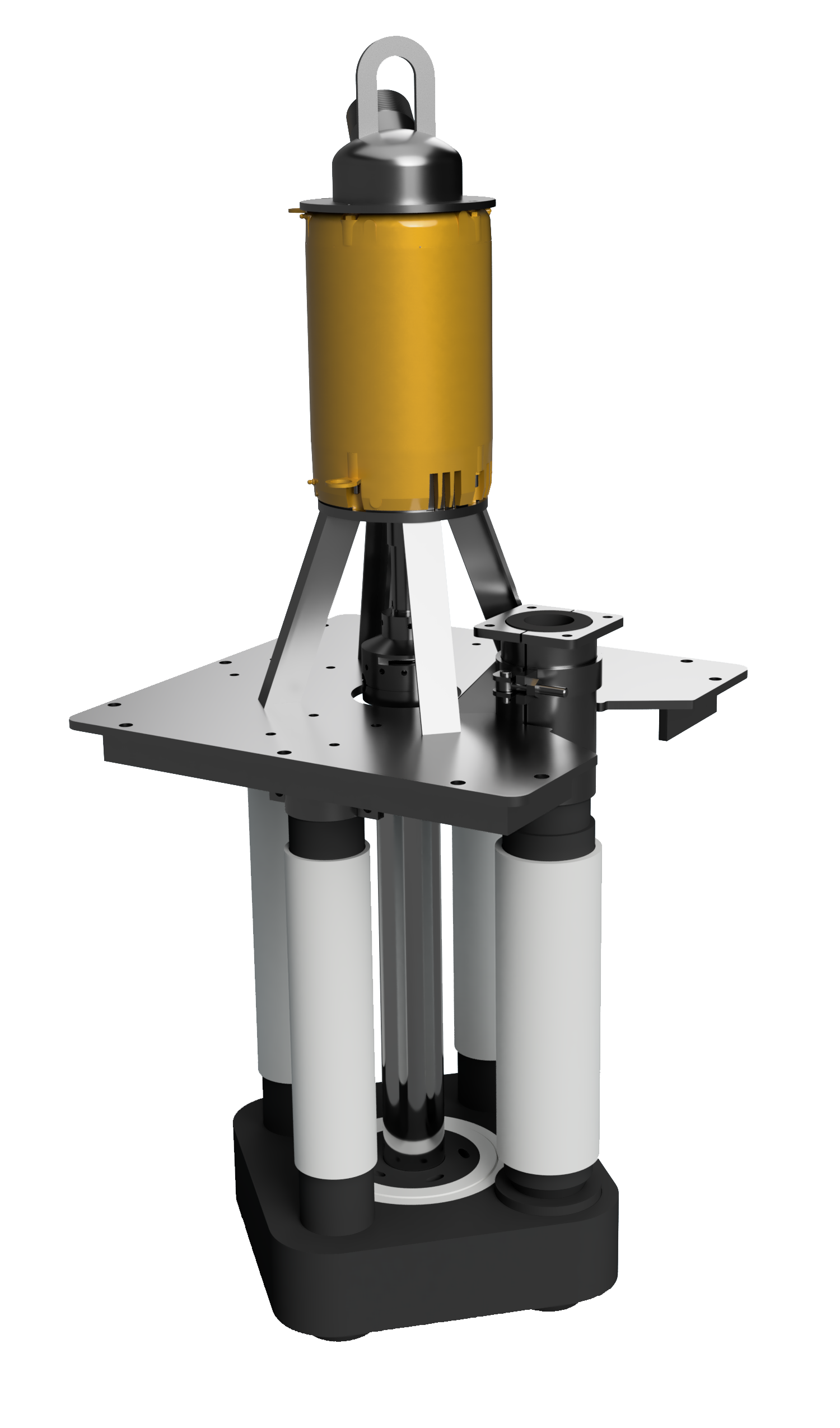

Transfer Pumps

We sell transfer pumps in a wide range of sizes and flow rates to meet your production requirements. Applications include transfer from melting to holding furnaces, filling transport ladles, alloying and pump-out operations, etc. Each pump is designed for the smallest possible footprint with the most efficient and reliable impeller technology.

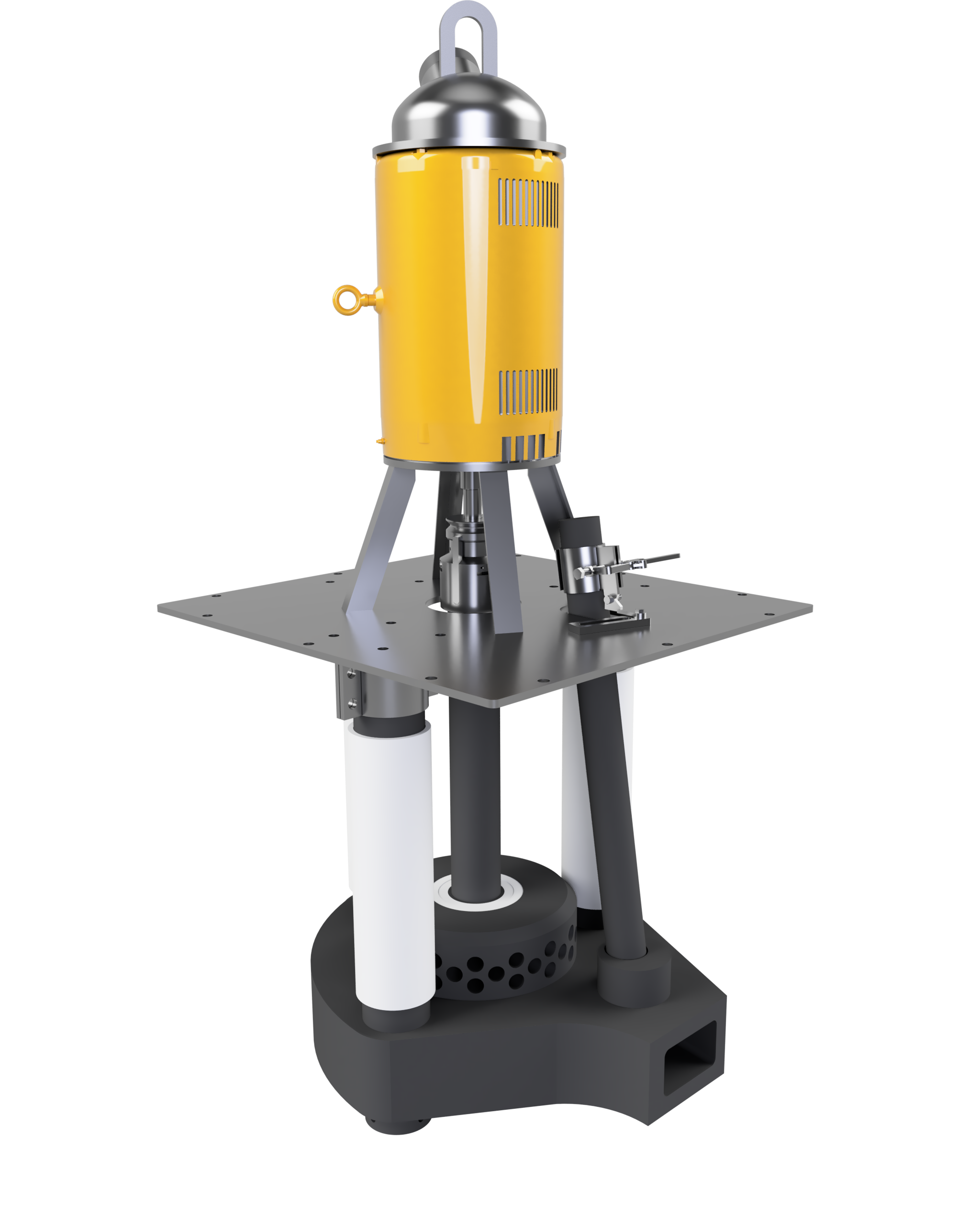

Circulation

High Temperature Systems high-efficiency circulation pumps are designed for your application requirements and carefully constructed to ensure optimal reverberatory melting furnace operation. Ideal circulation rates not only help maximize metal quality, but also improve furnace efficiency and reduce maintenance costs.

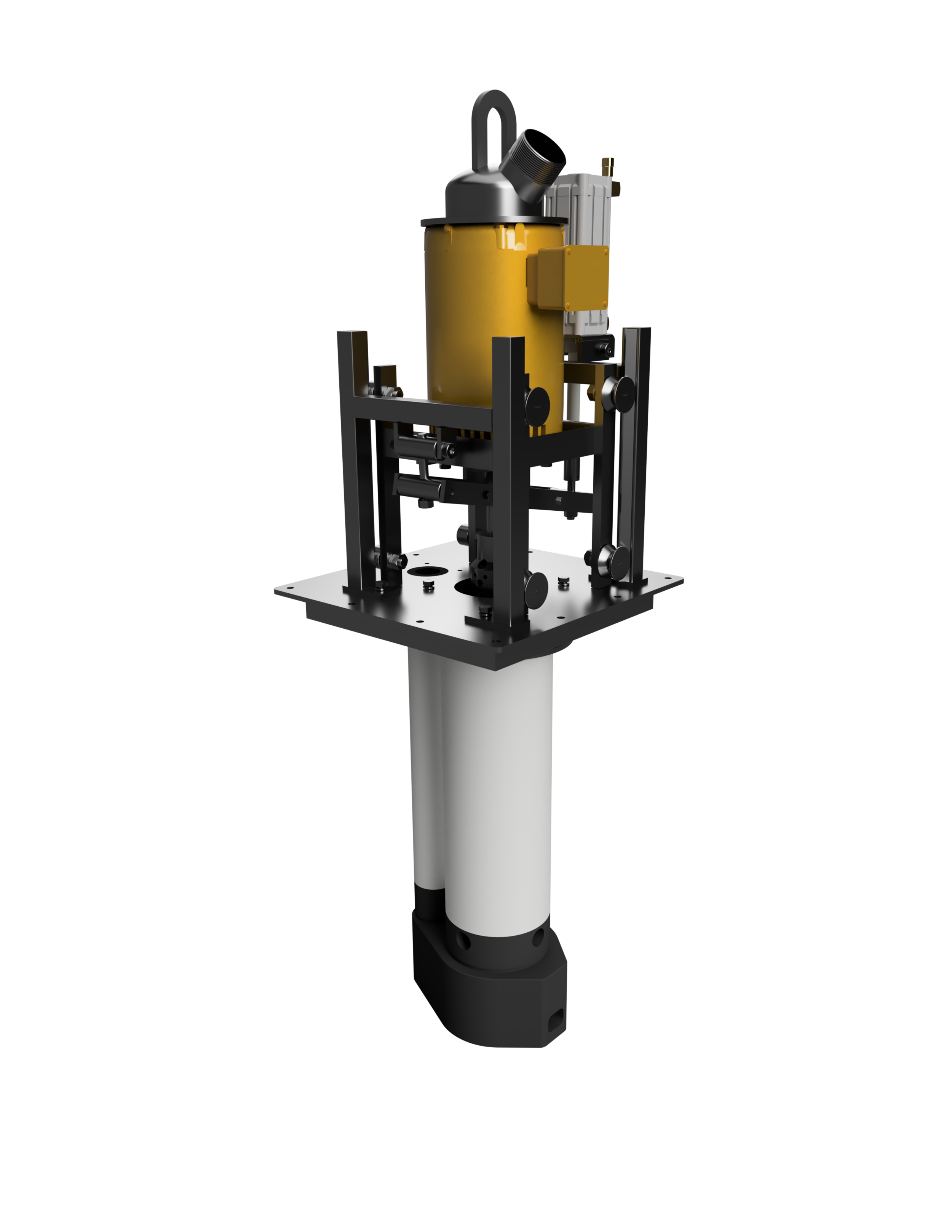

Chameleon®

The Chameleon® is a transfer pump combined with the features of a circulation pump in a single package! Our patented dual-volute design provides high reliability and circulates metal continuously while providing transfer-on-demand capabilities without the cost and complexity of installing two pumps in the pump well. This unique design is only available from HTS.