Articles

Cover Gas in Secondary Aluminum Melting

In the realm of secondary aluminum melting, refining, and recycling, the utilization of cover gas stands as a pivotal technique for enhancing process efficiency and product quality. Cover gas, essentially an inert gas blanket, serves to shield molten aluminum from the detrimental effects of atmospheric oxygen interaction, mitigating oxidation and dross formation.

Low Air Flow Freezes Pumps!

The primary reason for molten metal pump freezing is "slow starts." A slow-start is defined as slowly increasing the motor RPM. When a transfer pump is slow-started, the hot metal flows gradually into a cooler riser. As the metal temperature decreases, it solidifies or freezes inside the riser. This slow-start condition typically results in permanent damage and the need to rebuild the pump or at the very least replace the riser.

Expertly Optimized Solutions

High Temperature Systems, Inc. partners with melt department managers, supervisors, and engineers to craft complete solutions and solve problems that are beyond the reach of industry off-the-shelf solutions. Drawing from our standard product lines and more than 50 years of experience, we can craft solutions unique to your applications and furnace implementations. These solutions encompass aluminum, zinc and lead operations from die casting to galvanizing.

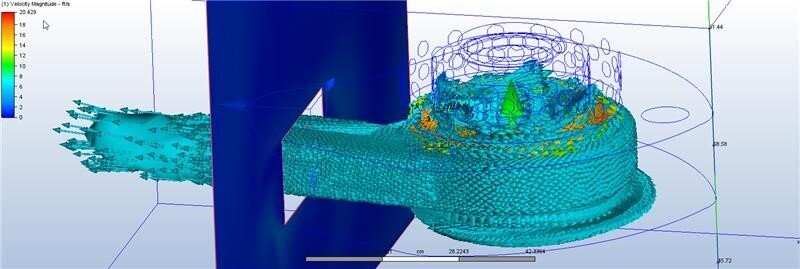

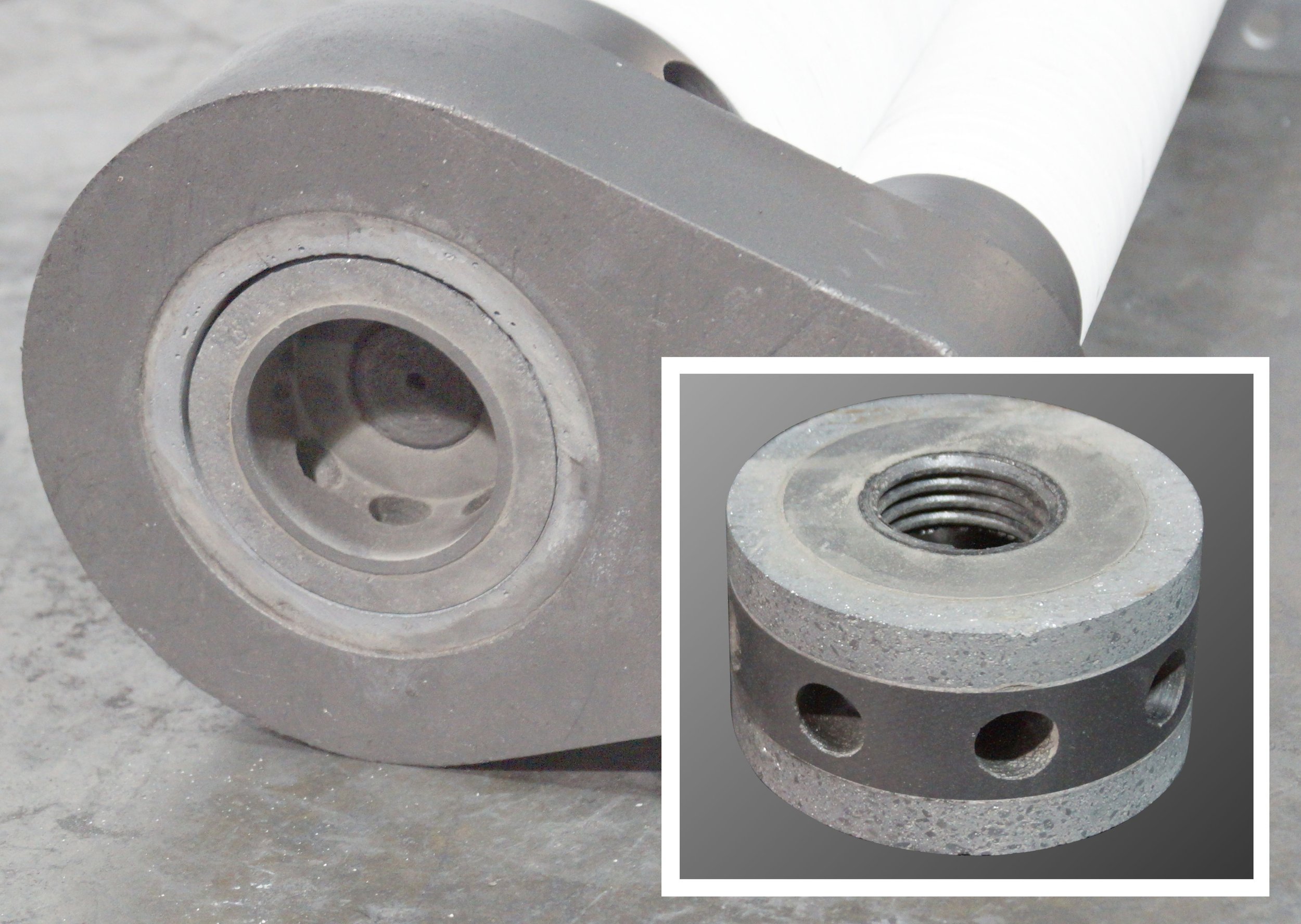

Impeller Types and Purposes

We offer three different types of impellers for many of our molten metal pumps. (The impeller is the vaned wheel that spins inside the pump base.) The impeller and its interaction with the pump base (and base volute) largely determine the performance characteristics of a given pump design.

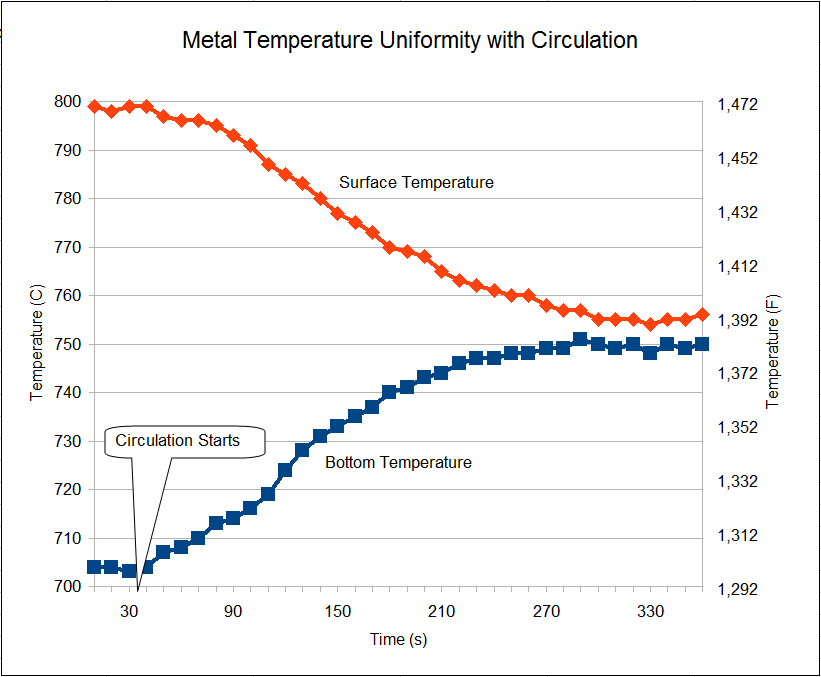

Why Should I Use a Circulation Pump?

In most real world applications, any one of these benefits results in savings that more than offsets the cost of a circulation pump. As an example, a properly sized and operated circulation pump can increase overall furnace throughput 15% and in some cases 30% for a small fraction of the cost of a furnace expansion project.

Small Pump Well? You need a Chameleon!

Re-use of a Graphite Pump - Not a Warped Idea!

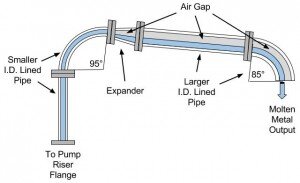

Like a Launder, Only Better!

A launder is used to transport molten metal. The basic construction of a launder is a steel trough lined with refractory material to insulate the molten metal from the steel. (Insulating both thermally and chemically.) The molten metal will lose heat as gravity draws it down the launder. If the heat is lost too quickly, the metal will freeze in the launder. There are a number of factors that influence the rate of heat loss including: