Pump Installation Planning Guidelines - Part 1 - Start at 40,000 ft!

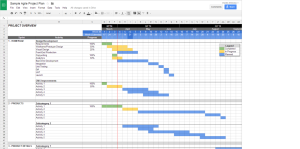

project schedule molten metal pump installation

Like any worthwhile venture, proper planning and resourcing are critical components of success. Do not let the project schedule scare you away from an important investment. Planning a new pump installation is non-trivial and should be treated as a facilities project. It is best to start with a 40,000 ft view that includes all aspects of the operation.Every installation has unique challenges that are difficult to generalize in a tech note. Taking the time to identify every impact and risk, and developing risk mitigation plans are strongly recommended. High Temperature Systems, Inc. can share our experiences with you to help develop a plan for maximum success.Besides the new pump and spares, there are a number of operations resources and stakeholders involved in properly installing a new pump system:

Production Planning - Pump installation will disrupt furnace operations for several hours. This translates into production slowdowns and product delays. These delays need to be managed at the operations level rather than trying to isolate them within the melt department. While some melt departments have sufficient backup capacity, any unforeseen failure in the backup capacity equipment will result in production delays; placing the production planner in a challenging position.

Facilities Engineering - Pumps require customized structural furnace interfaces. These interfaces require design and fabrication before pump installation. Additionally, pumps require power sources and may be electrically or pneumatically driven. Proper compress air supply lines, compressed nitrogen/argon supply lines, as well as electrical power interconnection, are required.

Manufacturing/Process/Quality Engineering - Manufacturing and process engineering departments must fully characterize all process changes to ensure product quality and operational efficiency.

Human Resources - In many cases, the addition new equipment results in staffing impacts. These include operation and safety training as well as staffing level changes.

Top Level Schedule DevelopmentCurrent Operation Assessment - Like all operations or facilities projects, an accurate assessment of the current operation needs to be made with all stakeholders. This evaluation should include a review of operations procedures, materials flow, and rates, process monitor data collection and analysis. This activity provides an accurate baseline for comparing performance and process quality.

Objectives, Goals, and Deliverables - The top-level objectives for the new system need to be quantified and agree upon by the stakeholders to avoid any confusion when planning and prioritizing. These might include melt rate goals or metal transfer time goals. Each stakeholder should have a list of quantified deliverables required to meet the objectives and goals.

Scheduling Installation, Startup, and Training - With a complete understanding of the current operation and the stakeholders deliverables, a project schedule can be developed. Gaining buy-in from each stakeholder is critical for success.

Planning for Contingencies - Lastly, planning for contingencies like project delays will help bring the stakeholders together should any unplanned events alter the project schedule. Also, contingency planning will assist in developing a spare part budget as well as temporary staffing levels.

In Part 2 we will examine the fine detail of the pump startup scheduling and expectations.