Air Supply Considerations for an Air Motor on a Molten Metal Pump

Our pumps are offered with air motor options. Air motor benefits include:

No electrical connections and associated complexities.

Pump speed is easily controlled by regulating the air pressure.

The pump can be run from a nitrogen bottle during maintenance or emergencies.

Air motors run cooler than ambient temperatures.

Air motors are lighter weight than their equivalent horsepower electric motor.

Air Pressure - All of our pumps use air motors with a maximum recommended air pressure of 100 psi (690 kpa). A combination of pressure and volume determines motor speed. In most cases, maximum motor speed is not desirable, so a regulator is required to moderate the pump speed.

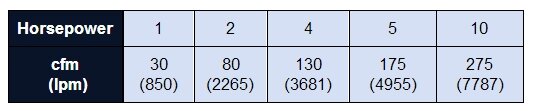

Air Volume - The necessary volume of air (cfm/lpm) is a function of the horsepower rating of the motor. This table provides reasonable guidelines:

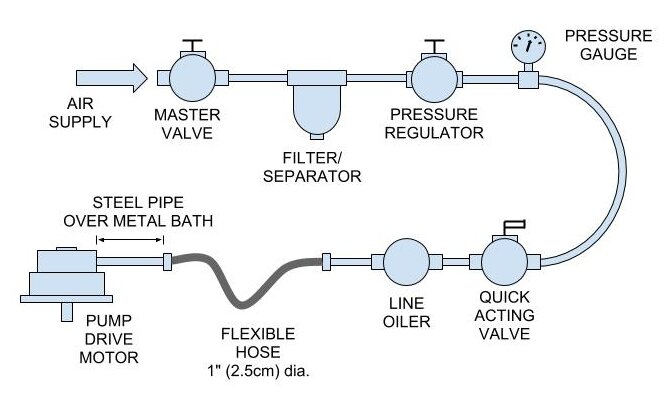

The illustration below shows an ideal air supply setup for an air motor used in a high-temperature application:

Important considerations:

The master valve is used to cut off the air supply for servicing the air supply components including the filter, regulator, oiler, etc.

The master valve location may be selected based on safety considerations. Closing the master valve or the quick acting valve will stop the operation of the pump.

The factory air supply may be “CDA” or clean, dry air. If this is the case, eliminating the filter/separator is acceptable.

The quick acting valve is typically a simple quarter turn ball valve located for ease-of-use and operator safety.

A flow meter may be installed in series with the pressure regulator to provide additional operating information.

The line oiler provides lubricant to the air motor. Due to the high temperatures of this application, the oiler must be located away from the molten metal bath.

In most applications, it is desirable to use a flexible air hose between the oiler and the air motor. We recommend a 1” (2.5cm) air hose.

The flexible air hose should not be subjected to convective heat flow from the metal bath, so a length of steel pipe is used to span the molten metal bath.

Maximum airflow is crucial:

Use only FULL FLOW VALVES such as ball and gate valves.

Do not use needle valves. These will restrict flow.

Do not use quick-couplings. These also restrict peak flow.

Twist claw connectors can be used, 3/4” minimum, 1” recommended

NOTE - Maximum airflow is the only way to ensure proper air motor operation and significantly reduce the risk of freezing the pump.