Articles

Transfer Pump Types

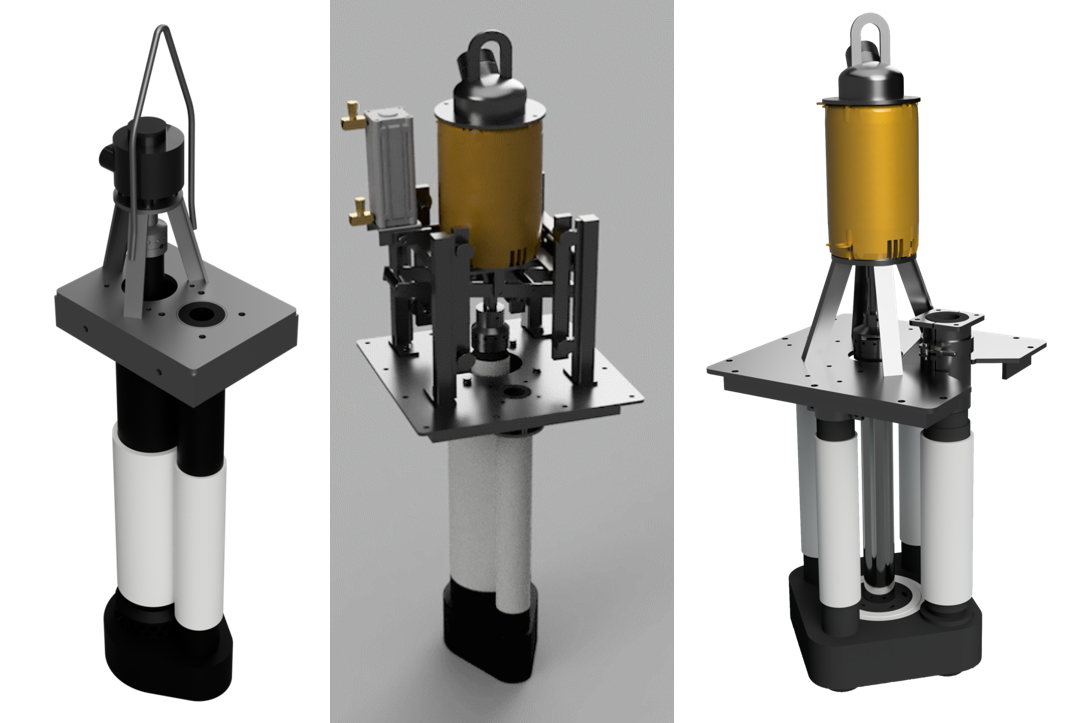

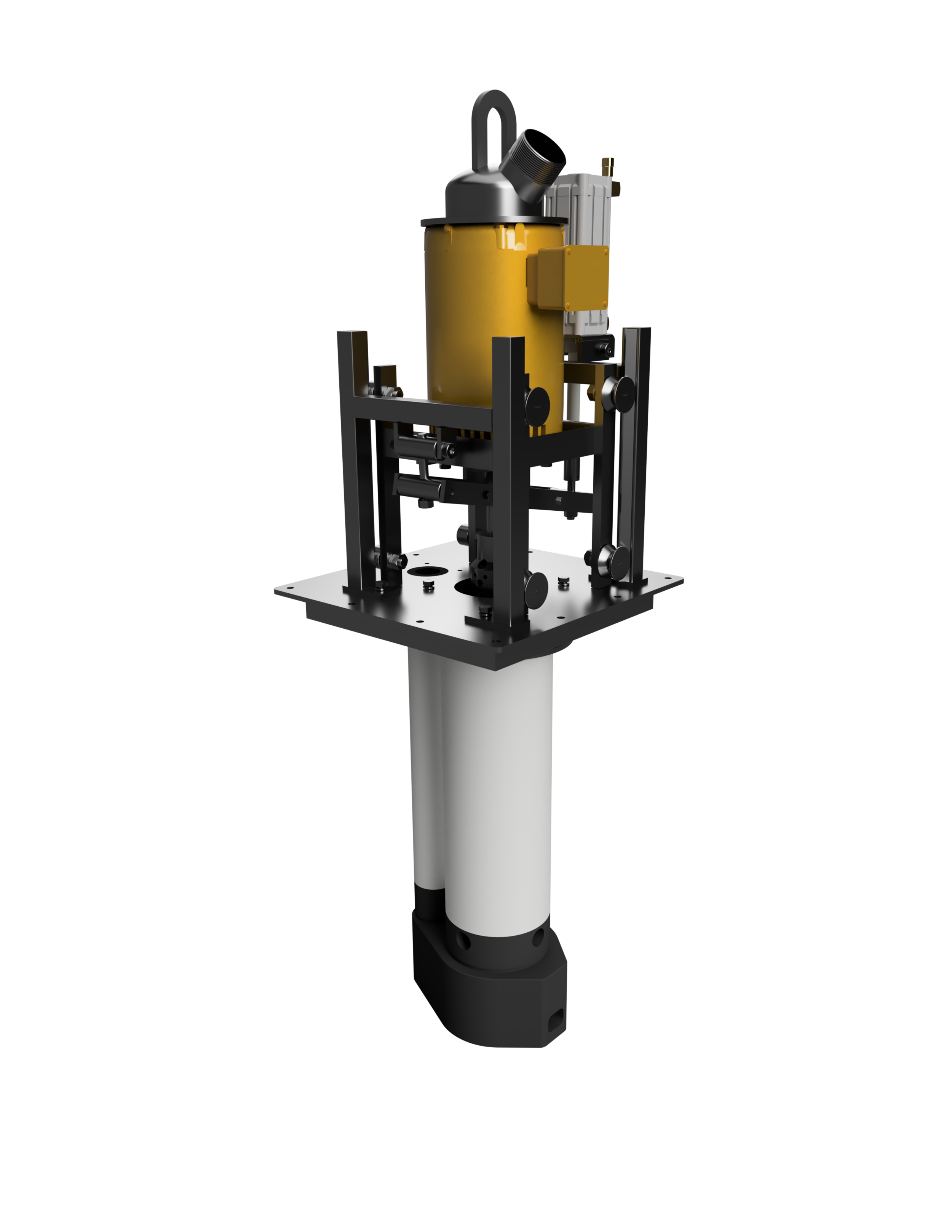

Closed, Dual Position, and Open Style transfer pumps are available in a range of sizes to accommodate any applications.

Expertly Optimized Solutions

High Temperature Systems, Inc. partners with melt department managers, supervisors, and engineers to craft complete solutions and solve problems that are beyond the reach of industry off-the-shelf solutions. Drawing from our standard product lines and more than 50 years of experience, we can craft solutions unique to your applications and furnace implementations. These solutions encompass aluminum, zinc and lead operations from die casting to galvanizing.

Circulate Continuously - Transfer on Demand

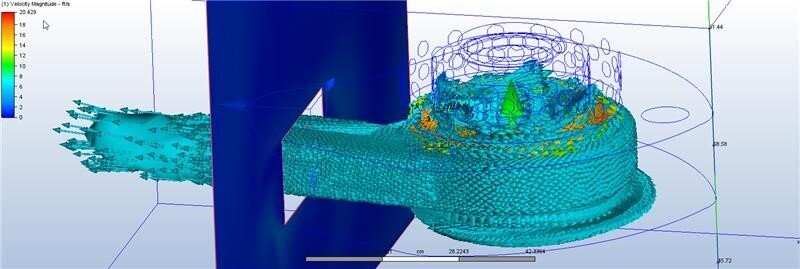

The ideal solution for these furnaces would be a single compact pump that performs both the circulation function and the transfer function. Such a pump would require a mechanism to redirect the output of the pump impeller to either a circulation nozzle or a transfer riser.

Pump Installation Planning Guidelines – Part 2 – Pump Startup Scheduling

In this article, we will examine the fine detail of the pump startup scheduling and expectations.

In this article, we’ll cover pump startup scheduling. We’ll cover prerequisites before getting started, special considerations, and how to plan for contingencies when things don’t go as planned.

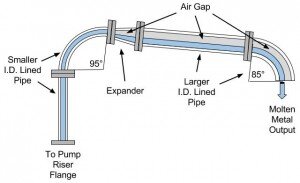

Like a Launder, Only Better!

A launder is used to transport molten metal. The basic construction of a launder is a steel trough lined with refractory material to insulate the molten metal from the steel. (Insulating both thermally and chemically.) The molten metal will lose heat as gravity draws it down the launder. If the heat is lost too quickly, the metal will freeze in the launder. There are a number of factors that influence the rate of heat loss including: