Articles

Transfer Pump Types

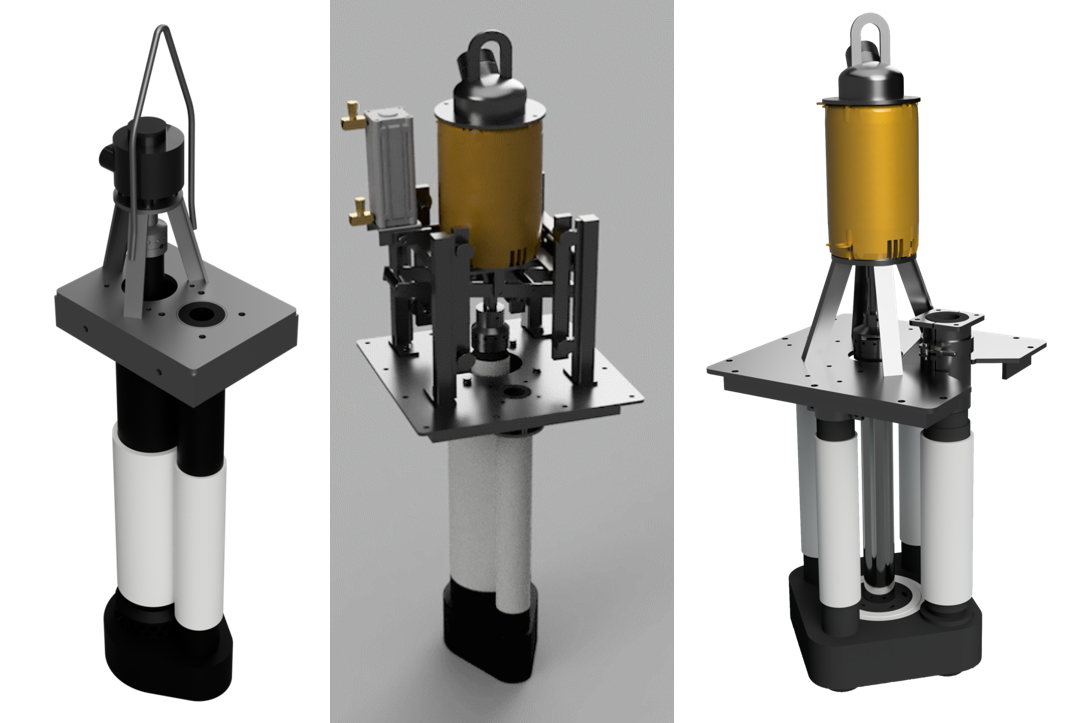

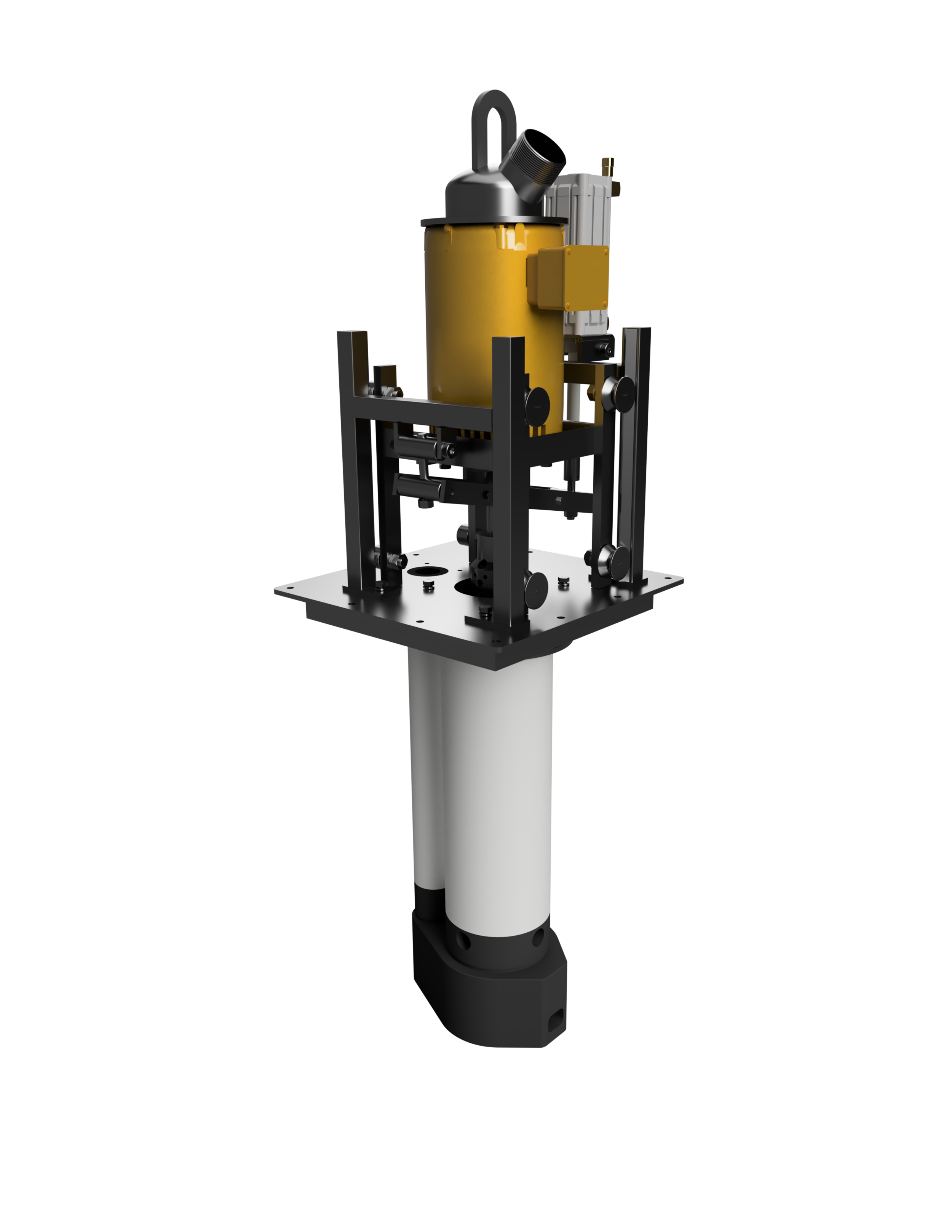

Closed, Dual Position, and Open Style transfer pumps are available in a range of sizes to accommodate any applications.

Intelligent Control for the Smart Foundry

Nearing the quarter of the 21st century, it seems technology is advancing faster and faster every year. Why shouldn’t your facility advance too? This post will provide some options for you to consider as you’re researching, designing, and improving your process.

Expertly Optimized Solutions

High Temperature Systems, Inc. partners with melt department managers, supervisors, and engineers to craft complete solutions and solve problems that are beyond the reach of industry off-the-shelf solutions. Drawing from our standard product lines and more than 50 years of experience, we can craft solutions unique to your applications and furnace implementations. These solutions encompass aluminum, zinc and lead operations from die casting to galvanizing.

Circulate Continuously - Transfer on Demand

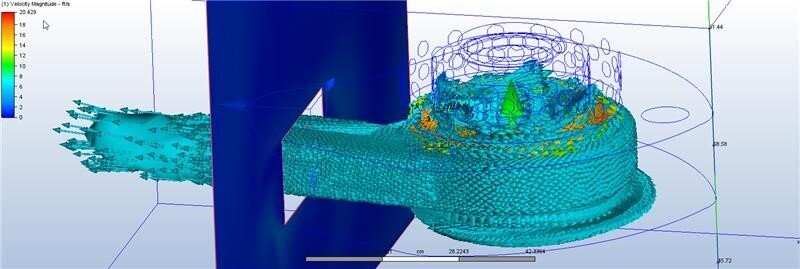

The ideal solution for these furnaces would be a single compact pump that performs both the circulation function and the transfer function. Such a pump would require a mechanism to redirect the output of the pump impeller to either a circulation nozzle or a transfer riser.

Pump Installation Planning Guidelines – Part 2 – Pump Startup Scheduling

In this article, we will examine the fine detail of the pump startup scheduling and expectations.

In this article, we’ll cover pump startup scheduling. We’ll cover prerequisites before getting started, special considerations, and how to plan for contingencies when things don’t go as planned.

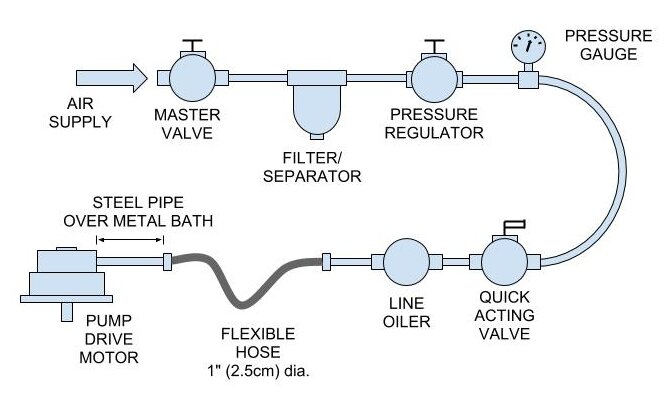

Air Supply Considerations for an Air Motor on a Molten Metal Pump

This article reviews important considerations for using an air motor with a molten metal pump. We will review the benefits of an air-powered motor, what an ideal setup looks like, and factors to consider in your setup.

Graphite - Non-Wetting in Molten Zinc

3-Phase Motor Running Backwards?

This post is one of the most frequently viewed on our website. This can be attributed to the high frequency of worn and damaged wiring. With proper electrical maintenance and pump startup procedures, this problem can be 100% eliminated.

Motors must be wired correctly to ensure proper pump operation. Incorrect wiring may cause the pump to turn backwards, resulting in several negative outcomes.

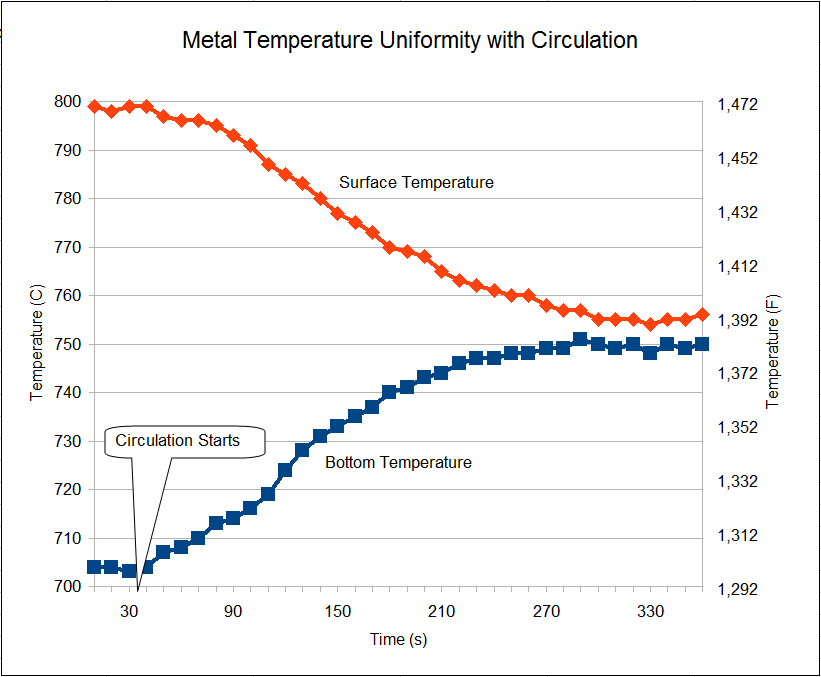

Why Should I Use a Circulation Pump?

In most real world applications, any one of these benefits results in savings that more than offsets the cost of a circulation pump. As an example, a properly sized and operated circulation pump can increase overall furnace throughput 15% and in some cases 30% for a small fraction of the cost of a furnace expansion project.

Re-use of a Graphite Pump - Not a Warped Idea!

Unlike stainless steel pumps, graphite pumps can be quickly and easily reintroduced into the molten metal bath, and the pump will operate with the same efficiency as when removed from the melt. This capability is because graphite retains its structural and dimensional integrity while stainless steel becomes flexible and deforms at molten metal operating temperatures. Once removed from the metal bath, especially an aluminum bath, the stainless steel pump must be discarded due to excessive deformation. Molten metal pump base showing posts, shaft, shaft bearing, and base all made of graphite treated with a proprietary oxidation inhibitor process not available elsewhere.

NEVER RUN A PUMP DRY!

The molten metal IS the lubrication for the impeller and base-volute. Running the pump dry will result in damage.

Pre-Storage Pump Inspection - Maintenance Pumps

Before putting a pump away for storage, it must be inspected. This article covers the step-by-step process to take before stowing a pump.

Preheating Stations

While not an absolute requirement, most molten metal pump operators benefit from utilizing a preheat station. These benefits include less downtime between pump changes, reduced risk of damage to the pump, decreased preheat time, and improved safety.