Line Reactors Improve Pump Motor Performance

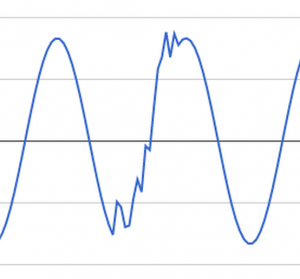

Dirty Power

Surprisingly few industrial facilities conduct power line quality assessments as part of routine maintenance. In a heavily mechanized environment, fast-transient power disruptions are common place. These fast transient events travel through out the power circuits and are stopped only by the power distribution transformers. This means that each individual piece of equipment must be designed to tolerate the electrical power environment in which it is installed.

Not all VFDs (Inverters) are Created Equal

So called "Inverters" or more correctly named Variable Frequency Drives (VFDs) that are used to control the speed of AC induction motors will tolerate dirty power to differing degrees. In most cases, the VFD digital control circuits are heavily shielded from power line disruption by virtue of their on-board DC power supplies and decoupling capacitors. The high power switching circuits that drive the induction motor are not as well protected, and may pass on or even amplify transient events. When a transient event is amplified by a 10HP VFD, the motor may respond with a sudden change in speed.

Potential Pump Damage

Powerful motors moving large amounts of molten metal is no place for sudden unwanted events. Under the worst of circumstances, an amplified power transient can cause shearing of pump shaft safety pins or breaking of shafts. (All molten metal pumps from High Temperature Systems are equipped with a safety coupling that either sacrifices shear pins or shafts to prevent catastrophic damage to structural pump components and preserve operator safety.)

Line/Load Reactors

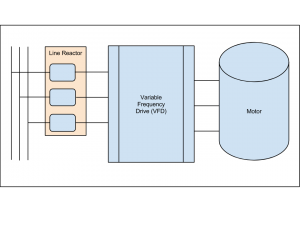

Line/Load reactors are specifically designed to operate with VFD drives.

When used with a VFD, the Line reactor is placed in series between the power mains and the VFD (The connection between the VFD and the induction motor remains a direct connection). The "reactor" in "line reactor" refers to the reactive or inductive characteristics of the line reactor component. An inductor opposes changes in flow of electrical current. Line/Load reactors have reactance values that allow the low frequency power to pass, while blocking high frequency power.

A line reactor is recommended when the service power is notably prone to voltage surges, spikes or transient signals.

A load reactor is generally recommended when the distance between the load terminals and the pump motor is greater than 100ft.

Line/Load reactors are specified by voltage, power, and either 2-phase or 3-phase (most pumps use 3-phase power). Typical line/load reactors for pump applications will be 460V with a HP (power) rating at least 25% higher that the maximum motor power. For instance, a 7.5HP motor will require a 10HP line reactor.

Line/Load reactors are optional on all motor control panels sold by High Temperature Systems.