Reduce Melt Loss AND Reduce Your Carbon FootPrint!

Surface dross generation rates are affected by several factors including:

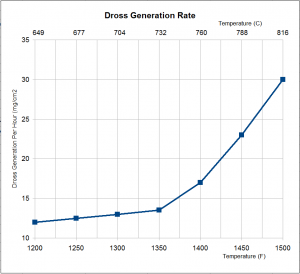

Metal Temperature - Often "dominates the equation" above 730°C (1350°F).

Surface Area - Can be moderated by a heavy argon cover gas.

Turbulence - Induced by flow and mechanical systems, increases effective surface area.

Direct Incorporation - Mechanisms that force gas and dross below the metal surface.

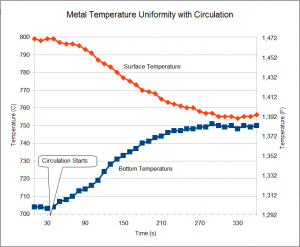

The diagram above illustrates how the molten metal temperature affects dross generation rates. At 790°C, the dross generation rate literally doubles as compared to 730°C. Conversely, if the furnace was operating at 800°C and the temperature was reduced to 730°C, the surface dross generation rate would be cut by 70%! By incorporating good circulation practices and reducing furnace temperatures, the dross generation rate can be significantly reduced. Consequently, you can reduce metal loss while reducing your carbon footprint.