Best ROI for Your Furnace

Pumping up Sustainability: The Best ROI for Energy Efficiency & a Greener Future

In the world of aluminum production, achieving optimal energy efficiency and minimizing metal loss isn’t just about cost savings; it’s a critical step towards a greener future. If you’re looking to improve your bottom line and your environmental impact, optimizing your reverberatory aluminum melting furnace is a key strategy. Let’s explore how to maximize your ROI while supporting a more sustainable aluminum industry.

Understanding the ROI of Energy Efficiency

The reverberatory furnace is a cornerstone of aluminum melting, but it’s also known for its high energy consumption. Improving its efficiency can yield substantial savings, both financially and environmentally. Employing optimally designed forced circulation leads to better ROI. In fact, improving circulation with an optimal design is likely the best ROI for a reverberatory aluminum melting furnace.

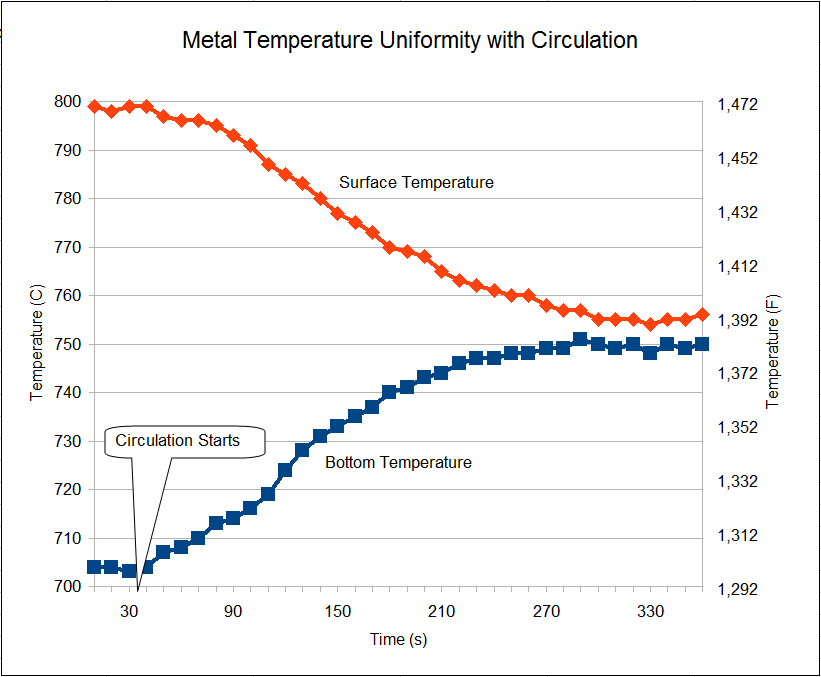

Reduced Fuel Costs: Optimal circulation reduces the temperature gradient of the metal bath in the hearth, both reducing the surface temperature while raising the bottom temperature. This increase the heat coupling from the roof into the surface of the melt while no longer needing to overheat the surface to ensure a minimal melt temperature at the bottom of the melt.

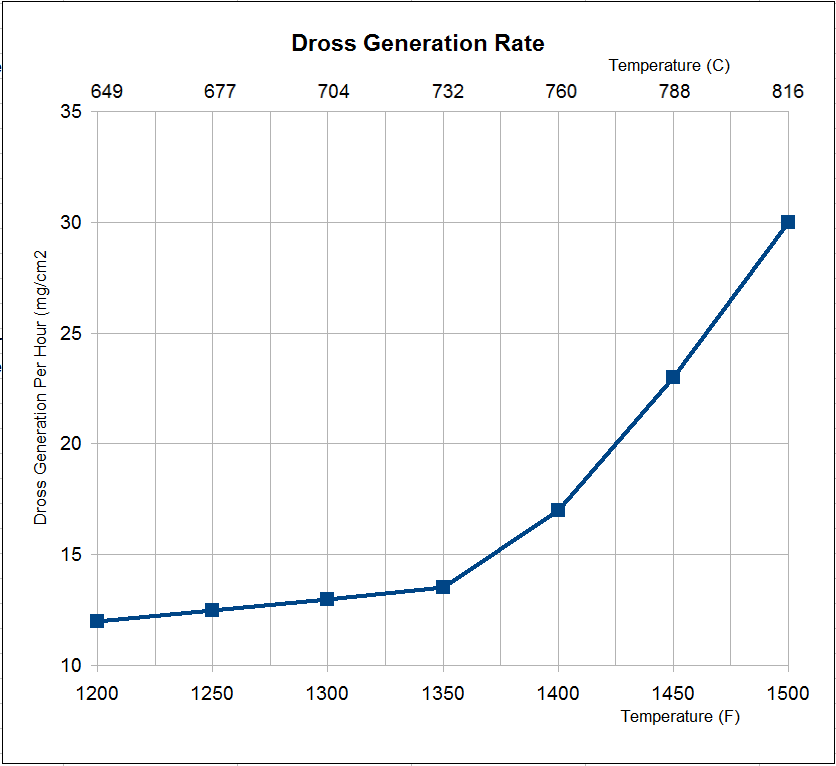

Decreased Metal Loss: Optimal circulation reduces surface temperature, leading to minimizing oxidation and dross formation, which means you’re losing less valuable aluminum during the melting process, further enhancing your profitability.

Increased Melt Rates: Proper circulation increases melt rates by keeping the charge bathed in hot metal and not allowing the charge to cool the surrounding area. This is true for both aluminum charge as well as alloying charge.

Lowered Emissions: Increased efficiency translates to reduced greenhouse gas emissions and other pollutants, helping your company meet sustainability goals and contribute to a cleaner environment.

Supporting the Greener Aluminum Initiative

The aluminum industry is actively working towards a more sustainable future. By investing in energy efficiency and metal loss reduction for your reverberatory furnace, you’re not just improving your ROI; you’re directly supporting these efforts.

Reduced Carbon Footprint: Lowering energy consumption and emissions contributes to a smaller carbon footprint for your company and the industry as a whole.

Resource Conservation: Minimizing metal loss helps preserve valuable natural resources and reduces the environmental impact of aluminum production.

Industry Leadership: By adopting greener practices, your company can position itself as a leader in sustainable aluminum production.

Conclusion

Improving the energy efficiency and metal yield of your reverberatory aluminum melting furnace is a win-win scenario. You’ll achieve a substantial return on your investment while contributing to a greener and more sustainable aluminum industry.

Take the first step today! Assess your furnace’s current performance and explore opportunities for upgrades and optimization. Your bottom line, and the planet, will thank you.

Let’s work together towards a more sustainable aluminum industry!