Articles

Cover Gas in Secondary Aluminum Melting

In the realm of secondary aluminum melting, refining, and recycling, the utilization of cover gas stands as a pivotal technique for enhancing process efficiency and product quality. Cover gas, essentially an inert gas blanket, serves to shield molten aluminum from the detrimental effects of atmospheric oxygen interaction, mitigating oxidation and dross formation.

Best ROI for Your Furnace

In the world of aluminum production, achieving optimal energy efficiency and minimizing metal loss isn’t just about cost savings; it’s a critical step towards a greener future. If you’re looking to improve your bottom line and your environmental impact, optimizing your reverberatory aluminum melting furnace is a key strategy. Let’s explore how to maximize your ROI while supporting a more sustainable aluminum industry.

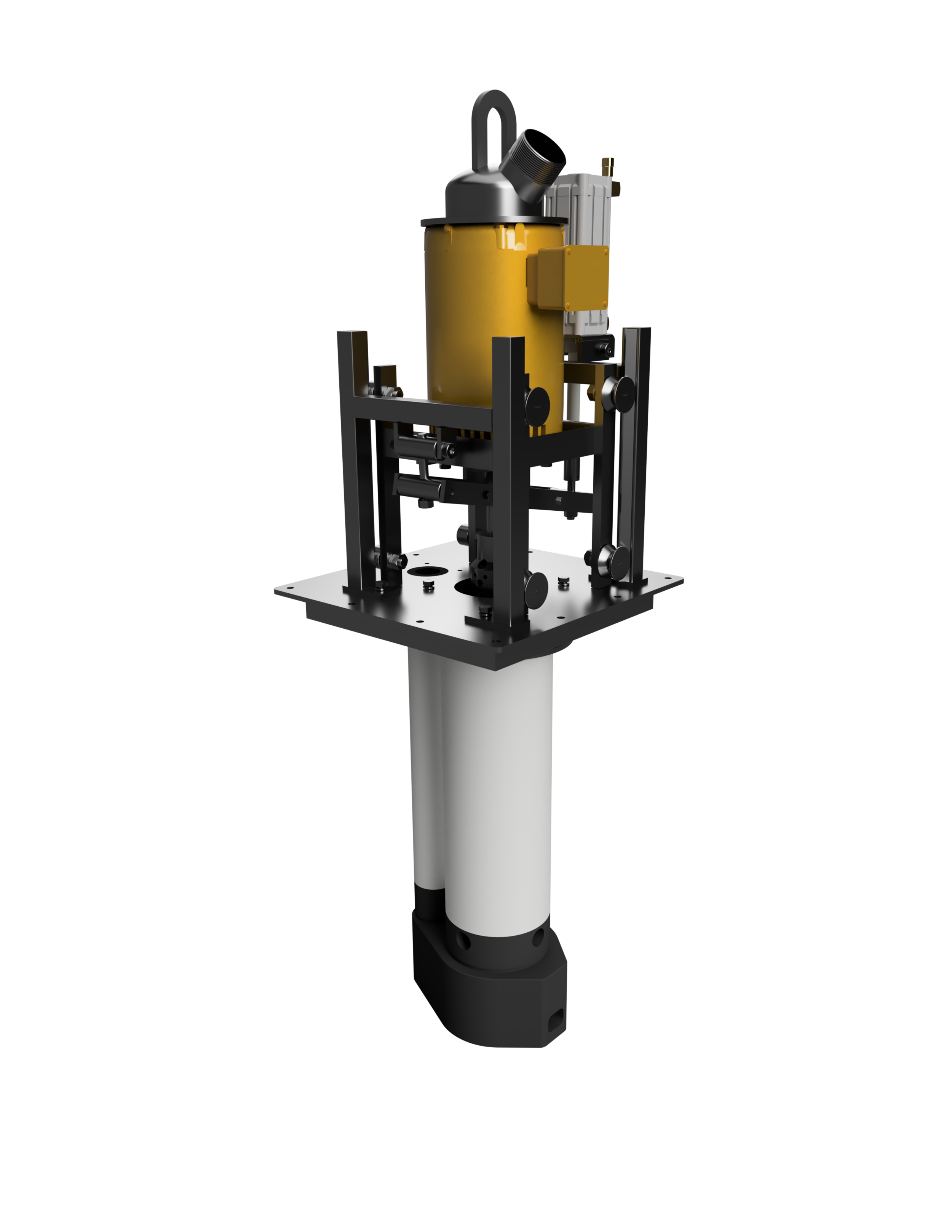

Circulate Continuously - Transfer on Demand

The ideal solution for these furnaces would be a single compact pump that performs both the circulation function and the transfer function. Such a pump would require a mechanism to redirect the output of the pump impeller to either a circulation nozzle or a transfer riser.