Articles

Quantitative Measurements and Characterization: The Key to Optimal Reverberatory Aluminum Melting Furnace Design

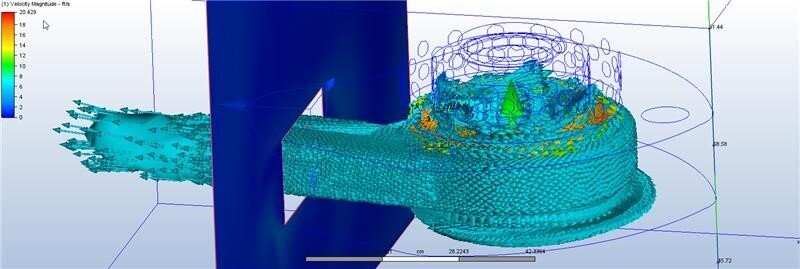

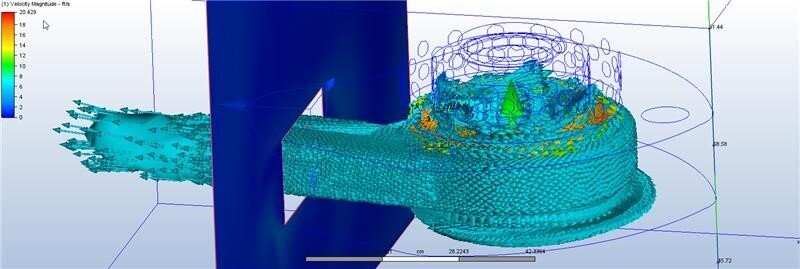

Designing an efficient reverberatory aluminum melting furnace is a complex undertaking. It requires careful consideration of various factors that directly affect its performance, energy consumption, and ultimately, your return on investment (ROI). Among these factors, the circulation pump’s sizing, placement, and control play a crucial role. Let’s explore how quantitative measurements and characterization lead to informed decisions in these areas, ensuring optimal furnace system design.

Best ROI for Your Furnace

In the world of aluminum production, achieving optimal energy efficiency and minimizing metal loss isn’t just about cost savings; it’s a critical step towards a greener future. If you’re looking to improve your bottom line and your environmental impact, optimizing your reverberatory aluminum melting furnace is a key strategy. Let’s explore how to maximize your ROI while supporting a more sustainable aluminum industry.

Expertly Optimized Solutions

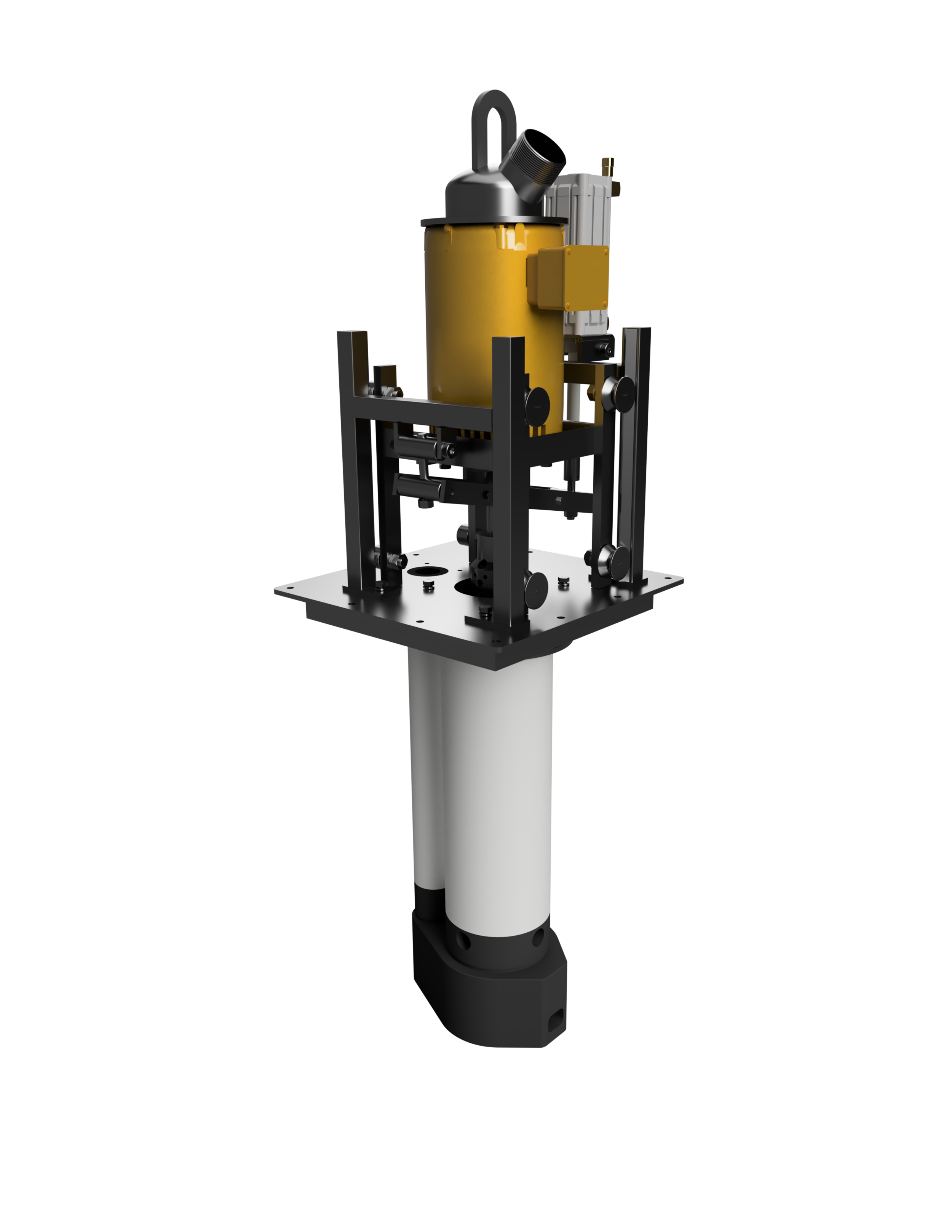

High Temperature Systems, Inc. partners with melt department managers, supervisors, and engineers to craft complete solutions and solve problems that are beyond the reach of industry off-the-shelf solutions. Drawing from our standard product lines and more than 50 years of experience, we can craft solutions unique to your applications and furnace implementations. These solutions encompass aluminum, zinc and lead operations from die casting to galvanizing.

Circulate Continuously - Transfer on Demand

The ideal solution for these furnaces would be a single compact pump that performs both the circulation function and the transfer function. Such a pump would require a mechanism to redirect the output of the pump impeller to either a circulation nozzle or a transfer riser.

Pump Installation Planning Guidelines – Part 2 – Pump Startup Scheduling

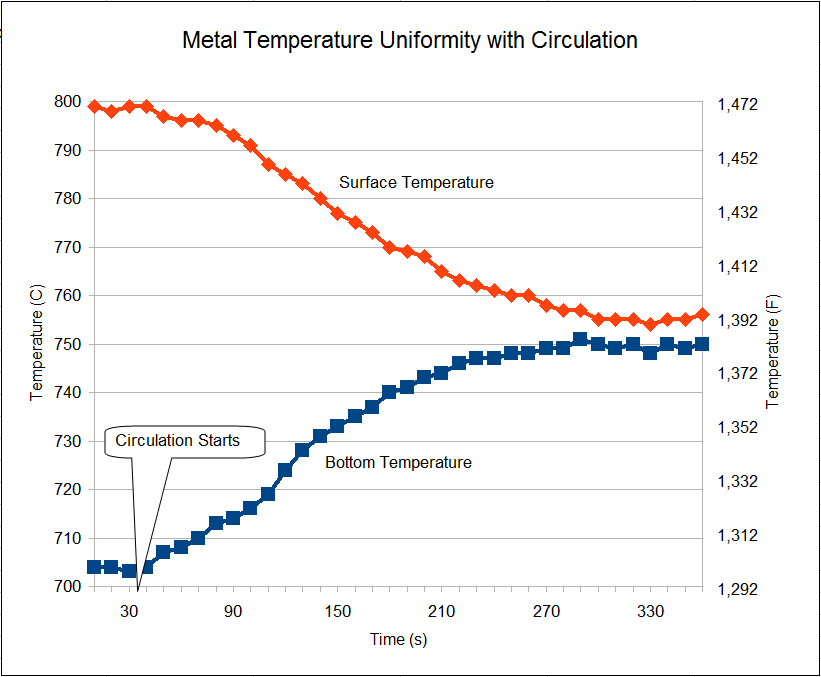

Why Should I Use a Circulation Pump?

In most real world applications, any one of these benefits results in savings that more than offsets the cost of a circulation pump. As an example, a properly sized and operated circulation pump can increase overall furnace throughput 15% and in some cases 30% for a small fraction of the cost of a furnace expansion project.

Reduce Melt Loss AND Reduce Your Carbon FootPrint!

NEVER RUN A PUMP DRY!

SLOW STARTS FREEZE RISERS

It's worth saying more than once because a frozen riser is a big maintenance issue. In previous post we outlined the procedure for lowering a molten metal pump into the bath. Once the pump is properly lowered into the molten metal, the pump must be turned on or energized.