Articles

Reduce Melt Loss AND Reduce Your Carbon FootPrint!

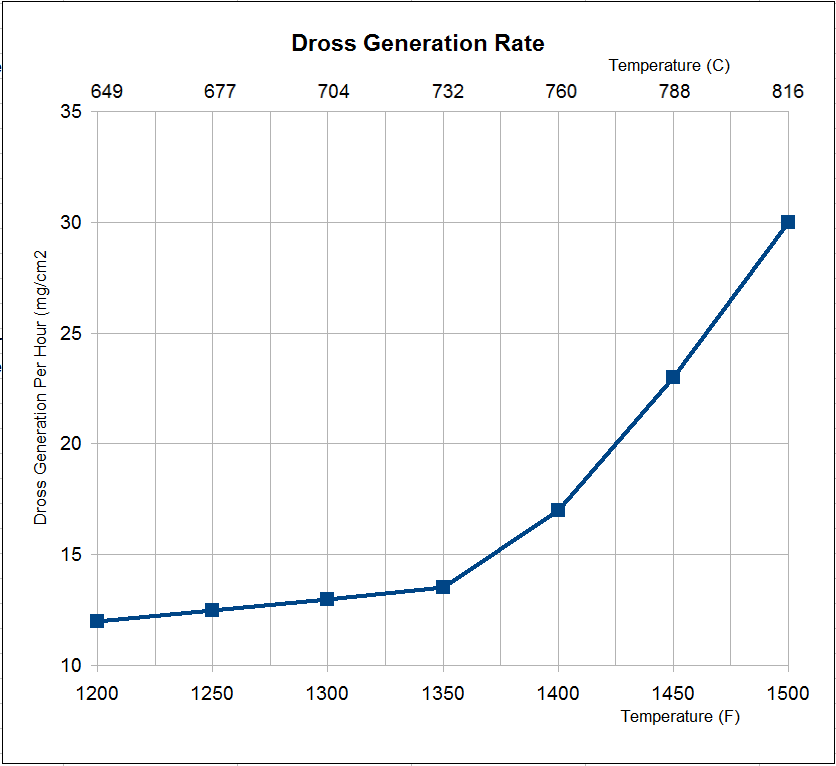

By incorporating good circulation practices and reducing furnace temperatures, the dross generation rate can be significantly reduced. Consequently, you can reduce metal loss while reducing your carbon footprint.

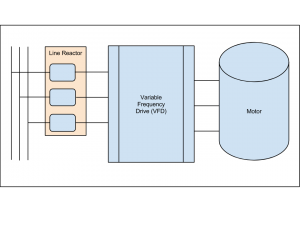

Line Reactors Improve Pump Motor Performance

Surprisingly few industrial facilities conduct power line quality assessments as part of routine maintenance. In a heavily mechanized environment, fast-transient power disruptions are common place. These fast transient events travel through out the power circuits and are stopped only by the power distribution transformers. This means that each individual piece of equipment must be designed to tolerate the electrical power environment in which it is installed.

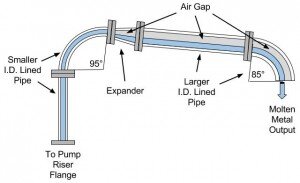

Like a Launder, Only Better!

A launder is used to transport molten metal. The basic construction of a launder is a steel trough lined with refractory material to insulate the molten metal from the steel. (Insulating both thermally and chemically.) The molten metal will lose heat as gravity draws it down the launder. If the heat is lost too quickly, the metal will freeze in the launder. There are a number of factors that influence the rate of heat loss including:

NEVER RUN A PUMP DRY!

The molten metal IS the lubrication for the impeller and base-volute. Running the pump dry will result in damage.

Pre-Storage Pump Inspection - Maintenance Pumps

Before putting a pump away for storage, it must be inspected. This article covers the step-by-step process to take before stowing a pump.

Preparing the Pump for Storage - Operational Assessment and Removal from Metal

About 10% of pumps are used exclusively for scheduled furnace maintenance. Between usages, these pumps need to be properly stored and maintained.

Maintenance Pumps and Typical Use Cases

About 10% of molten metal pumps are used exclusively for maintenance applications. It is not uncommon to use a maintenance pump once every year to eighteen months. This article covers the typical ways that maintenance pumps are used.

SLOW STARTS FREEZE RISERS

This article reviews the three basic cases for energizing a pump, based on pump type.

Pump Installation - Lowering the Pump into the Molten Metal

This article reviews the standard procedure for introducing a pump into a molten metal bath.

Graphite Properties and Application in Molten Metal Pumps

Graphite is the refractory material of choice for many non-ferrous molten metal pump applications. This article provides a list of graphite characteristics that are important in pump applications.

Preheating Stations

While not an absolute requirement, most molten metal pump operators benefit from utilizing a preheat station. These benefits include less downtime between pump changes, reduced risk of damage to the pump, decreased preheat time, and improved safety.

Hoist Considerations

Before you use that shiny new electric hoist, consider this. Hoists that are not equipped with variable speed controls can be hazardous to your health and the health of your molten metal pump.

Rock Catcher Basics

Rock Catchers are used to keep large chunks of material from interfering with proper pump operation. Rocks, chunks, clumps, are all terms to describe material in the melt that is a bit too large to flow through the impeller’s orifices.